May 15, 2023 14:03 by

admin

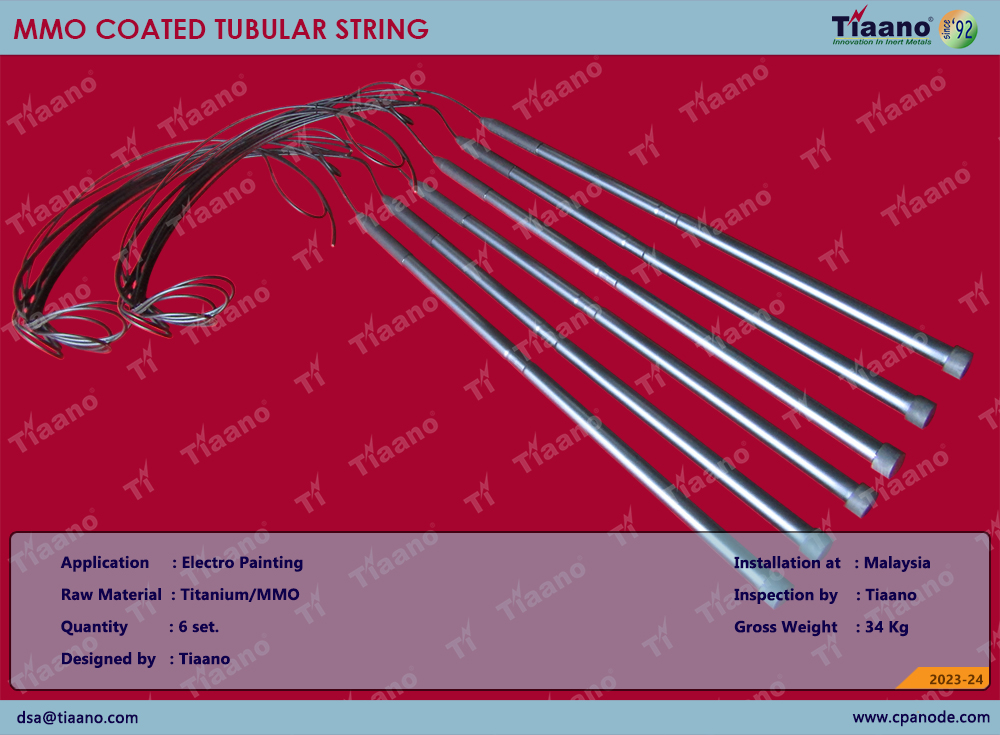

adminMMO anodes have the advantage of having a low consumption rate with a high current capacity, the consumption rate of the MMO anodes is only milligrams per Ampere/year, and because of this low wear rate, the metal dimensions remain constant throughout all of the anode life, thus providing a constant performance with a low resistivity.

This type of anodes is widely used for impressed current cathodic protection of deep and shallow anode beds, and in offshore applications as well.

MMO tubular anodes used in cathodic protection are hollow titanium tubes with a mixed metal oxide (MMO) coating that increase the titanium surface conductivity, these conform to the ASTM B338 grade I standard, and because of its light weight, the transportation fare is very low.

4e431e2c-92ff-431e-a1f1-93d872ce5e7e|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

May 15, 2023 13:56 by

admin

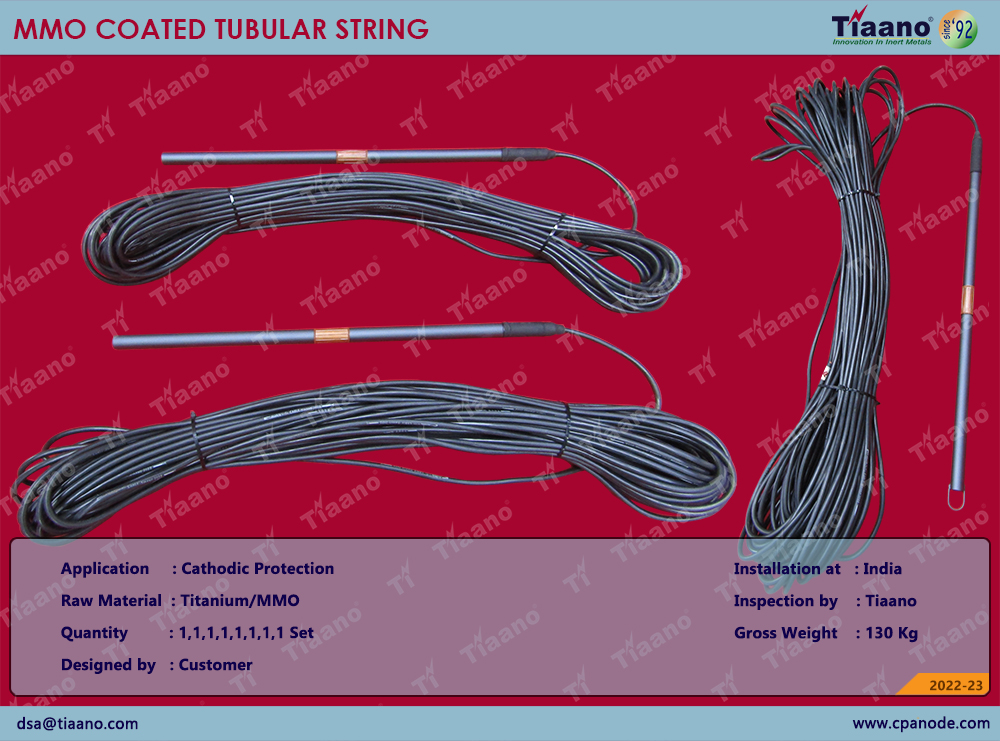

adminTitanium tubular anodes are manufactured using titanium seamless tube and coated with platinum group precious metal mixed oxide coating.

Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements.

Mixed metal oxide based electro catalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current.

Mixed Metal Oxide anodes are typically rated for a given output and life, for example 5 amps at 20 years. Within the normal range of current discharge for MMO anodes, this relationship is linear. The same 5 amp anode rated for 20 years of service would provide 40 years if only operated at 2.5 amps.

Benefits of MMO Coated Tubular String:

· Lightweight/Durable

· High current output

· Low cost

· Dimensionally stable

· High cost performance

7df314f3-64e4-4562-bb2f-f18291dd43af|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

May 11, 2023 10:58 by

admin

adminWe, Ti Anode Fabricators Pvt. Ltd., developed an extremely strong and electrically low resistance centre crimp connection, which ensures the lowest possible electrical resistance (less than 1.0 Milli Ohm) between the cables and anode tube. The Platinum group Mixed Metal Oxide coating is a crystalline electrically conductive coating that activates and enables a titanium substrate to function as an anode. Whether operating in fresh water, seawater, soil, or mud. MMO Coatings are extremely stable even in very low pH environments.

MMO titanium tubular anodes are coated with mixed metal oxide that has an extremely low consumption rate measured in milligrams per year. Unlike other types of anodes the consumption rate of MMO anode is negligible with the dimensions of the anode element remaining virtually unchanged during the operational service life of the anode. As a result, the power required to impress current will remain the same.

Cathodic protection system is a technique used to control a corrosion of a metal surface by making it the cathodic side of an electrochemical cell. Cathodic protection is an old and effective system that prevents forming rust in metal and helps in corrosion resistant. Corrosion can be prevented by eliminating the oxygen or the positively charged hydrogen ions.

2813b86b-5aaa-4c2b-a694-4bdb2f1df853|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

May 8, 2023 11:19 by

admin

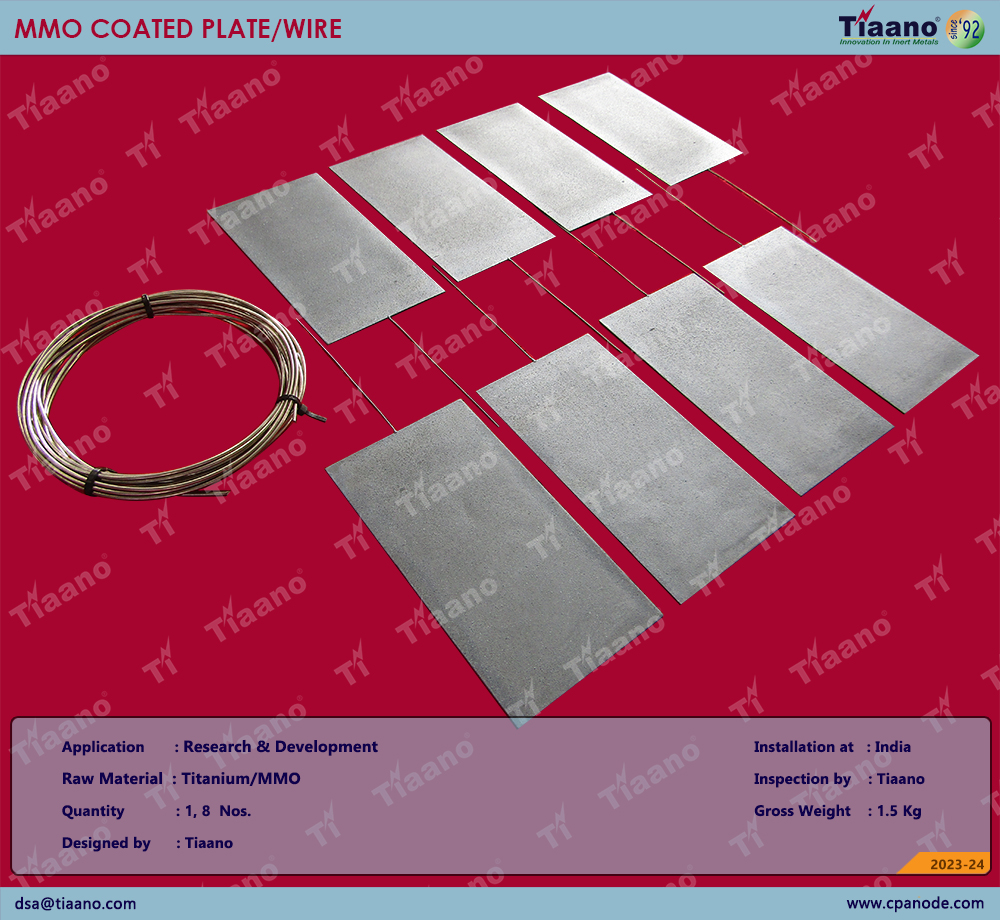

adminMMO coated anodes are widely used in various industries because it has special physical and chemical properties like high corrosion resistance, catalytic in nature and thermal conductivity.

MMO titanium anodes act as inert anodes and are non-consumable and long lasting. Ti's MMO coating has proven superior to other mixed metal oxide coatings currently being used.

Research and development (R&D) includes activities that companies undertake to innovate and introduce new products.

MMO coated titanium wire anode is suitable for direct burial in fine sand, carbonaceous backfill or immersion in fresh or saline waters. MMO-Ti wire anode can be connected to a feed cable at one end or ‘piggybacked’ to form a continuous anode suitable for installation under storage tanks or to provide continuous close protection for pipelines.

Wire anodes can also be used to protect the internal surfaces of water tanks where their malleable shape permits even current distribution in areas where there can be large variations in water level.

e2f97e4c-c930-4489-8508-2334932bd77f|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

April 19, 2023 11:00 by

admin

adminWe, Ti Anode Fabricators Pvt. Ltd., developed an extremely strong and electrically low resistance centre crimp connection, which ensures the lowest possible electrical resistance (less than 1.0 Milli Ohm) between the cables and anode tube. The Platinum group Mixed Metal Oxide coating is a crystalline electrically conductive coating that activates and enables a titanium substrate to function as an anode. Whether operating in fresh water, seawater, soil, or mud. MMO Coatings are extremely stable even in very low pH environments.

MMO titanium tubular anodes are coated with mixed metal oxide that has an extremely low consumption rate measured in milligrams per year. Unlike other types of anodes the consumption rate of MMO anode is negligible with the dimensions of the anode element remaining virtually unchanged during the operational service life of the anode. As a result, the power required to impress current will remain the same.

Cathodic protection system is a technique used to control a corrosion of a metal surface by making it the cathodic side of an electrochemical cell. Cathodic protection is an old and effective system that prevents forming rust in metal and helps in corrosion resistant. Corrosion can be prevented by eliminating the oxygen or the positively charged hydrogen ions.

f0d5f238-2aeb-47ef-90b6-1db1daddbcab|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

March 31, 2023 15:46 by

admin

admin

Current Feeder

Current feeder is commonly designed to impressed the current into the ICCP anode network, this feeder is equipped with high pressure sealed threaded connection, which will helps to impress the current externally while using the wire, ribbon , strip anodes for internal protections such as condenser Box, Pump internals, pipe internal, Basket strainers , storage vessels Etc.,

This current feeder is completely made of Titanium Material, so it can survive in any atmospheric conditions like the seashore. Feeder shaft is adequately insulated from connection nipple and tested at 300 VDC also process connector is equipped to install the enclosure for cable termination so it’s easy to make a seal proof connection.

This current feeder is improving the reliability of the ICCP system as most of the CP system were failure happened due to an improper electrical connection.

3dda8a92-d3f0-4538-8592-be538c3964dc|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

March 31, 2023 11:27 by

admin

admin

Tiaano MMO titanium tubular anodes are coated with mixed metal oxide that has an extremely low consumption rate measured in milligrams per year. Unlike other types of anodes the consumption rate of MMO anode is negligible with the dimensions of the anode element remaining virtually unchanged during the operational service life of the anode. As a result, the power required to impress current will remain the same.

Application

Marine structures, seawater intakes, deep well ground beds, horizontal ground beds, distributed anodes, tank internals & tank bottoms. Suitable for use in soils, mud, carbonaceous & petroleum coke backfill; fresh, brackish and sea-water.

8897fb4a-4191-4bb3-bd1c-c9e67321d7fd|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

March 30, 2023 17:13 by

admin

admin

Ti Anode Fabricators Pvt Ltd., India – having in-house facilities for manufactures ICCP anodes, for impressed current cathodic protection applications. Marine structures are commonly cathodically protected by impressed current Cathodic protection is effective for the embedded and submerged sections of the pile. It becomes less effective in increasing height of the splash zone where coatings need to be considered.

Cathodic Protection on Jetties

Cathodic Protection is a method to protect the steel pile wall of a jetty from corrosion. The Cathodic Protection on the steel piles works in the seawater and will only be active from the area below the splash zone and the bottom of the Splash zone jacket till in the seabed. The protection of the area covered on the steel pile in the seabed depends on the method of the Cathodic Protection.

ICCP Anode Design

The anodes are normally used in the form of solid titanium plate, rod or tube substrate, certain cases niobium may be used, if a higher operating voltage is required. The substrate is provided with mixed metal Oxide coating consisting of mainly IrO2/Ta2O5 and Platinum plating suitable for use in seawater. Platinised anodes perform extremely well in seawater environments exhibiting a large current density and an extremely low consumption rate

Electrolyte

Catalyst

Max. Current Density

Voltage

Design Life

Advantages

Seawater

MMO

600 Amps/M2

8 V

25 Years

Retain large current density, good conductivity, Long life in extreme environments and also low cost.

Platinum

1000 Amps/M2

8 V

25 Years

A large current density and an extremely low consumption rate

900d9cc3-e6df-4387-b6ce-901abfc6ead7|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

March 30, 2023 16:26 by

admin

admin

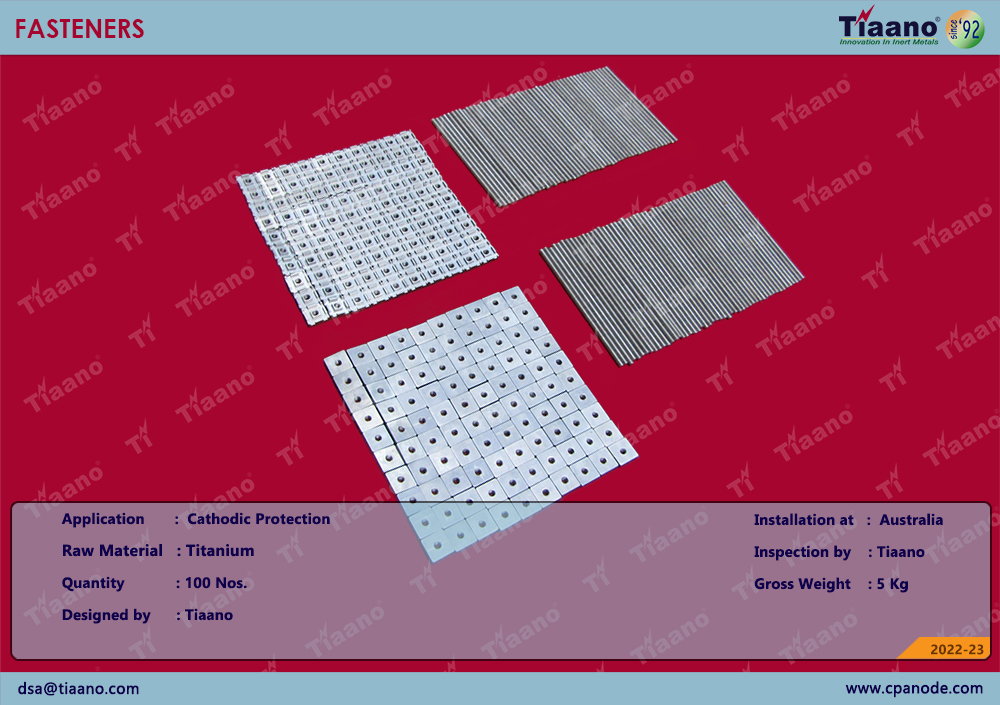

Ti Anode Fabricators Pvt Ltd., manufactures CPCC Canister Anode with their in-house facilities in India, for Impressed current Cathodic protection application. Using following alternative anode combinations are been supplied based on the customer’s interest.

Titanium expanded mesh with Ti’s MMO coating.

Titanium wire with Ti’s MMO coating.

Titanium expanded mesh with Ti’s Platinum plating.

Titanium wire with Ti’s Platinum plating.

Niobium wire with Ti’s MMO coating.

Niobium wire with Ti’s Platinum plating.

Application:

Shallow vertical and horizontal surface ground beds.

Underground storage tanks.

Aboveground storage tanks.

Pipelines.

Advantages over Silicon - Iron anodes:

Twice the life

Unbreakable

Lighter weight

Easier to install

Narrower trench

Easy to centralize

Reduce excavation and drilling cost.

Material Of Construction:

Canister: Galvanized steel tube

Substrate: Titanium, ASTM B 265 or 348 Gr.1

Niobium, ASTM B

Catalyst: MMO or Pt

Cable: XLPE/PVC, EPR/CSPE, KYNAR/HMWPE.

Cable ~ anode connection: CPCC equal to LIDA.

ead9f4ae-97c1-41e7-aab0-2b678c11b30e|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

March 28, 2023 10:42 by

admin

adminCathodic protection (CP) is a technique used to control the corrosion of a metal surface. Impressed current systems utilize an external power source that provides protective current to mitigate corrosion activity. Permanently installed anodes and the embedded reinforcing steel are connected to an AC/DC rectifier that forces the steel to a cathodic or protective condition. Impressed current systems provide a high level of protection but should be properly monitored and maintained to ensure long-term performance.

Platinized cantilever anode is used for protecting pipeline internals, suction and condenser box internal for 30 years and more by applying DC current with transformer rectifier. We use platinum/ MMO plating/ coating to increase the conductivity.

For more details visit these links:

www.cpanode.com,www.tiaanostore.in,www.tiaano.com

Follow us on:

Pinterest, Instagram, Facebook, Twitter

7cab4bff-a0df-47c9-a490-8f11dbfedebf|0|.0|27604f05-86ad-47ef-9e05-950bb762570c