August 2, 2022 17:46 by

admin

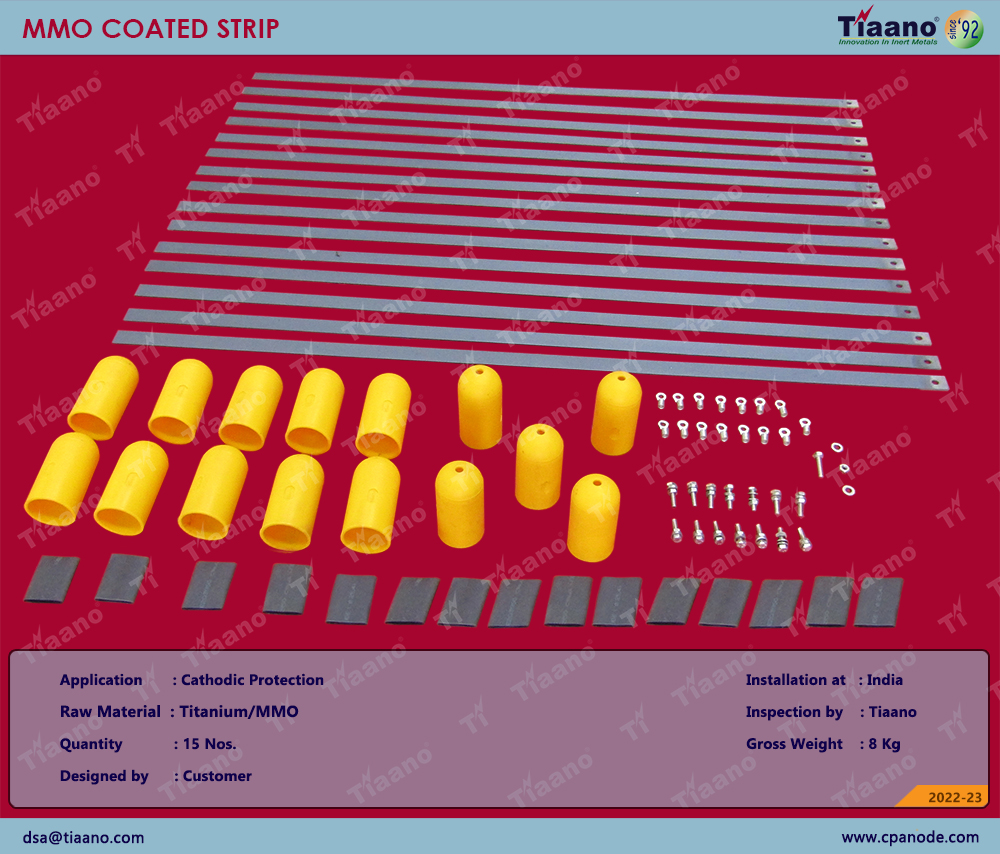

adminStrip anode is mostly utilized for the erosion insurance of seawater structure, Pilings, Piers, Jetties and drifting vessels and so on. Normally these anodes are utilized in the security of Seawater Application. Strip anode is a vital part for Cathodic Protection frameworks in seawater structures. It is made out of a valuable metal blended oxide impetus in the titanium plates by warm cycle.

Titanium strip anodes are fabricated utilizing titanium ASTM B 265 Gr. 1 or 2, Coated with Platinum bunch valuable metal blended oxide covering. MMO covering comprises of Ir and Ta and it is appropriate for use in all cathodic assurance applications. Since blended metal oxide anodes have a very low utilization rate, the titanium substrate stays consistent over the plan lifetime of the anode.

The leading anti-corrosion & uniform current distribution characters, it have great physical and mechanical properties of titanium. MMO covered anodes are emphatically suggested for Impressed Current Cathodic Protection (ICCP) application. We likewise fabricated and provided FRP Insulated Strip anode for different clients.

Impressed Current Cathodic Protection systems are the ultimate solution for all corrosion problems to protect the metallic structure for long time and are recognized as a superior alternative to sacrificial anode systems which require frequent replacement. Impressed current cathodic protection systems are preferred by ship owners because they reduce fuel cost and maintenance.

MMO Coated strip is used for concrete protection like jetty pile, underground pipes, pillars etc. Tiaano supplying FRP insulated strips with catalyst of MMO and Platinised. Tubular string anodes are used to protect the underground pipe lines from corrosion.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

904334f7-049f-454f-9a51-57fbcc64adb5|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 1, 2022 12:07 by

admin

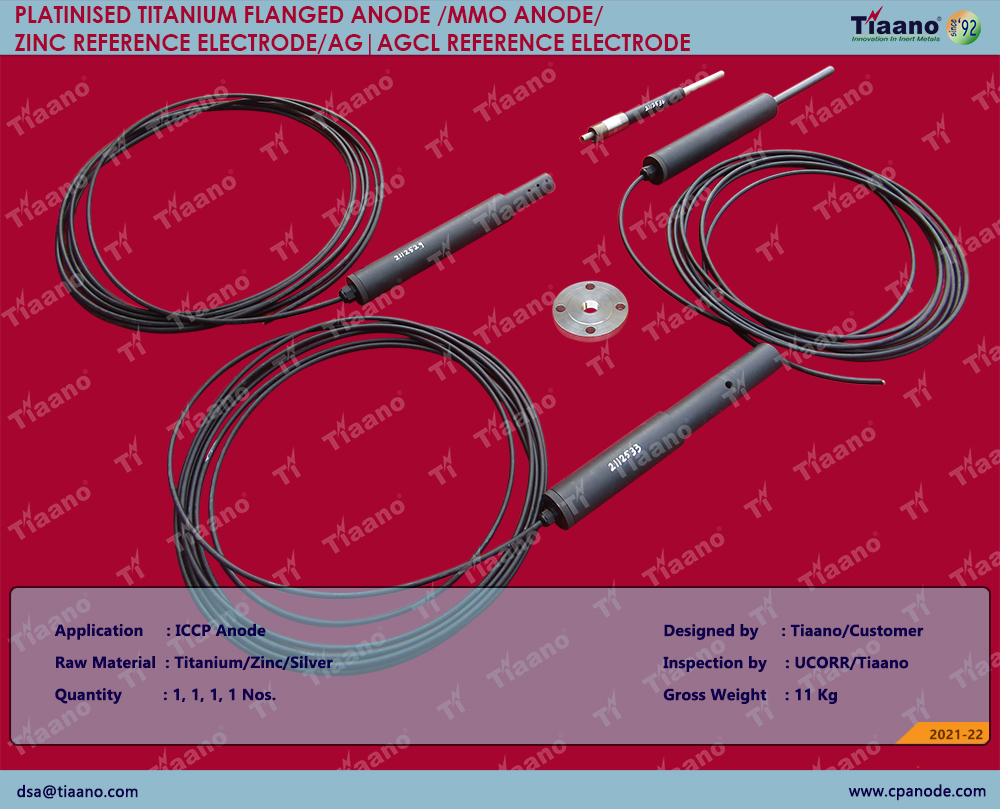

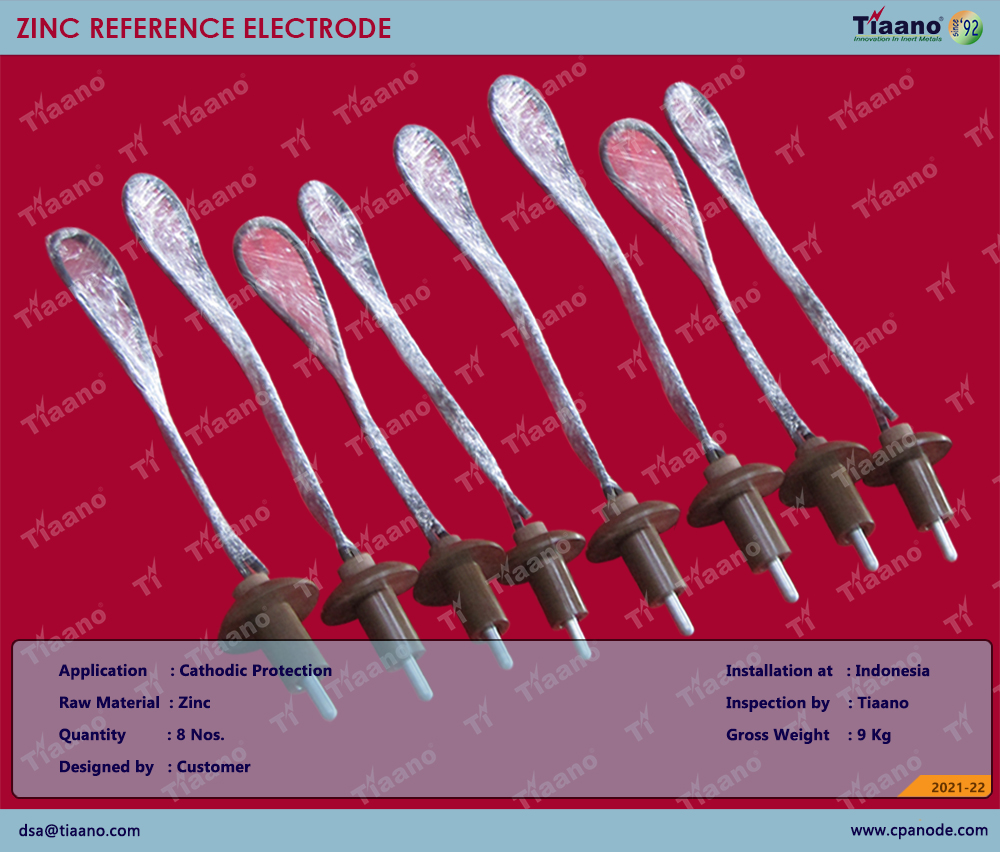

adminThe use of a metal reference electrode to measure potential difference in direct contact with the electrolyte around the structure may not make sense, but the reference zinc electrode in seawater is suitable for many applications. Successful samples have also been observed in the use of this electrode in the tanks bottom with the backfill, although many designs today use copper/ copper sulphate reference electrodes.

Zinc reference electrode is cheaper than silver/ silver chloride reference electrode and is used instead unless a high degree of stability is required. In addition, the mechanical stability of this type of electrode is much higher than other reference electrodes which have different and fragile components

High purity zinc ingots (minimum 99.9% with maximum iron content of 0.0014%) are used in the production of zinc reference electrodes. For connecting, a copper cable with chloride resistance coating and with 10 mm2 or 16 mm2 cross section is used and the cable is welded to the steel core inside the electrode. The interface between the copper cable and the steel rod is coated with epoxy resin.

MMO Coated cantilever anode are used to protect the surface of gigantic pump internals and condenser box where the sea water pass through in it. These anodes are use to protect the pump internals from erosion and corrosion with impressed current.

Reference electrodes are used in locations where a constant, stable reference where our anodes are installed with constant potential rectifiers.

Normally we can use wide variety of reference electrodes like zinc, silver chloride or copper sulfate reference electrodes for pump internal, condenser water box/vessel applications to monitor the cathodic protection anodes activeness.

Tiaano supplying MMO & platinum plated cantilever anodes and zinc reference electrodes for cathodic protection.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

5c067b6d-5ad4-430d-a1cf-4ef5fbb2d5be|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

July 27, 2022 17:29 by

admin

admin

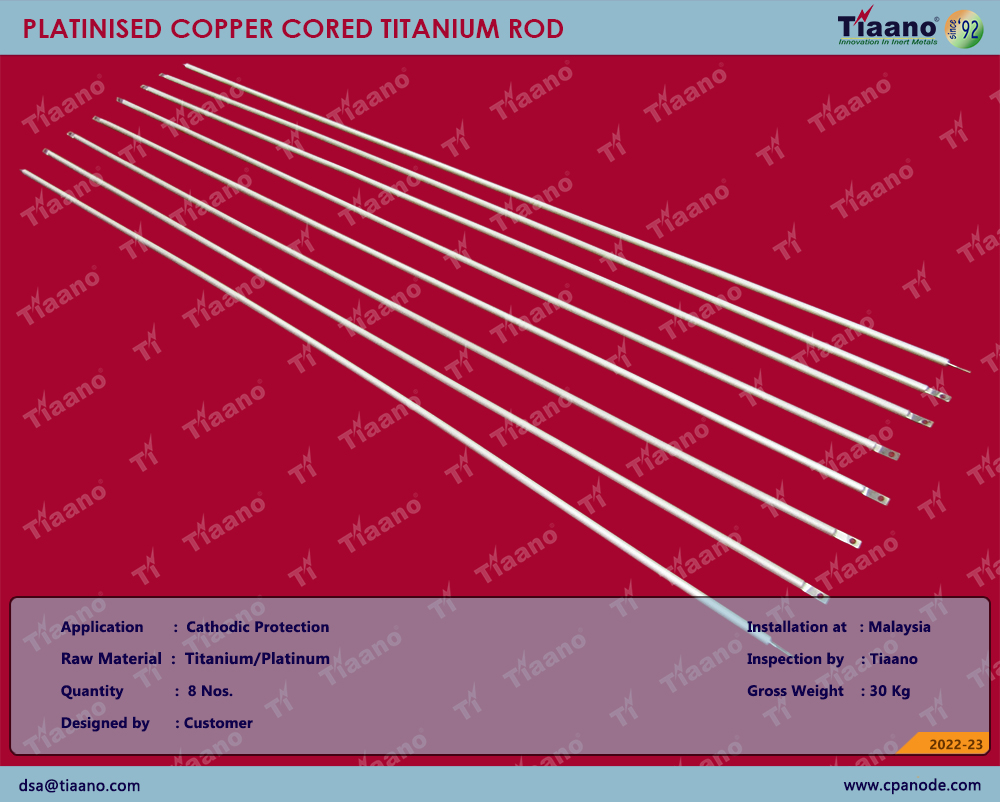

PLATINISED COPPER CORED TITANIUM ROD

Platinized titanium anodes are extensively used in electrolytic processes. They have successfully replaced lead anodes in electroplating applications due to their lower consumption, dimensional accuracy, ability to form precise deposit thicknesses on desired geometric shapes, predictable plating chemistry and ease of maintenance. These anodes can be designed and formed with various geometries based upon the parts to be electroplated.

Platinum on titanium anodes are highly preferred anodes for electrodeposition of copper, chromium, platinum, nickel, palladium and gold.

Platinized titanium anode by adopting thermal decomposition process to get a dense wear-resistant layer of platinum coating. The anode surface is modified to improve adhesion of platinum and to significantly improve uniformity of coating thickness, also reduce the coating porosity imparting greater acid resistance to the anode. This platinum coated titanium anode can be fabricated into bar, rod, sheet, mesh and other customized shape to meet your special needs.

Because of its high conductivity and low consumption rate, Platinum is an excellent anode material. Due to its high cost, Platinum is made practical for use by electroplating a thin layer over a high corrosion resistance substrate. Since Titanium, Niobium and Tantalum substrates have the ability to form an insulating oxide film under anodic conditions, they are commonly used as anode in ICCP (impressed current cathodic protection anode). Among them, Titanium is less expensive; however, it has a much lower breakdown potential than Niobium or Tantalum. The titanium oxide breaks down at anodic potentials in the 12 V range.

Advantages of platinized titanium anodes

Low consumption rate and high current density

Voltages in excess of 10 Volts will result in severe pitting of the titanium core causing premature failure

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

8730cea2-7309-4f2f-be20-436e3dc27e35|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

July 21, 2022 18:09 by

admin

admin

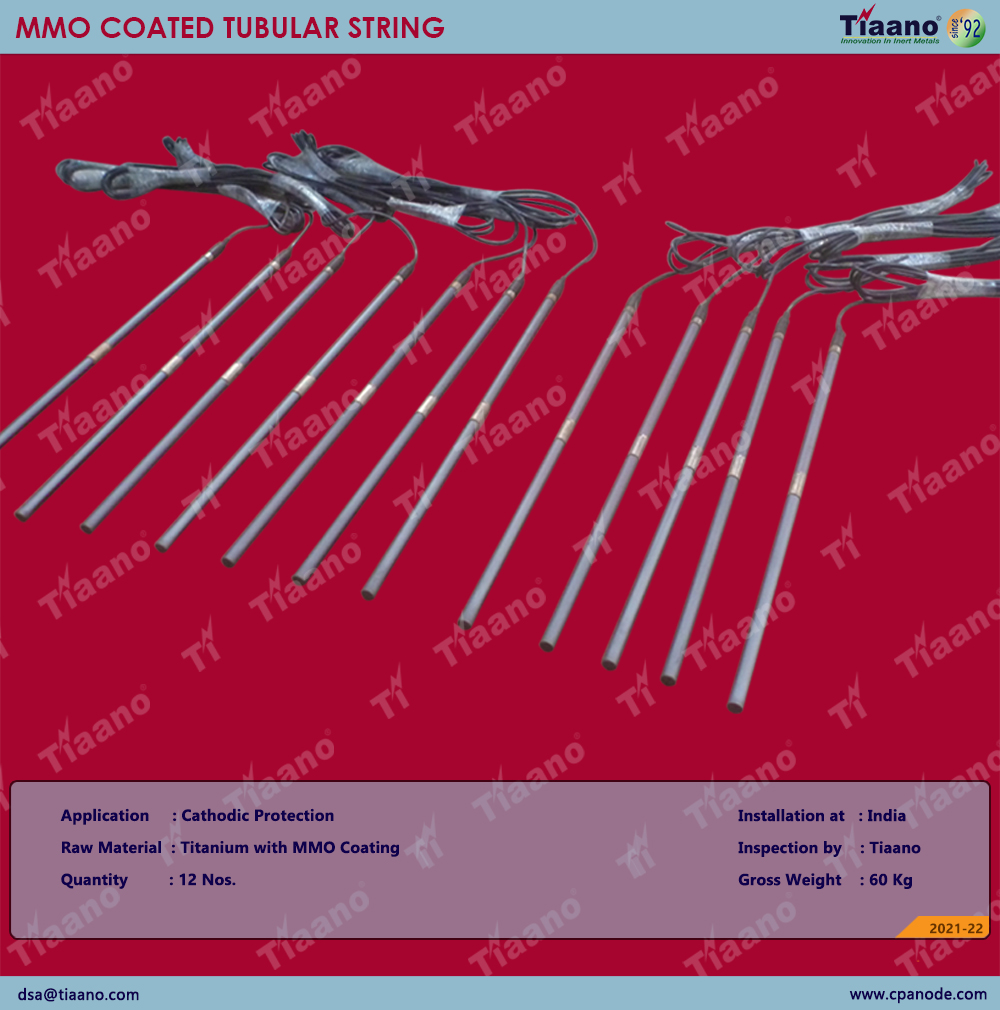

MMO Coated Tubular String for Cathodic Protection

We Tiaano do fabrication & supply of MMO Titanium tubular anodes by using titanium seamless tube and coated with platinum group precious metal mixed oxide coating. Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements

Mixed Metal Oxide Coated Titanium anode design for the demands of deep anode beds, shallow beds and the earth’s natural waters. MMO Tubular anodes are dimensionally stable anodes which remain constant throughout all of the anode life, thus providing a constant performance with a low resistivity MMO Titanium tubular anodes are a titanium tube base with a mixed metal oxide conductive coating and itself an excellent electronic conductor.

The design life of the anode varies with operating current in a variety of applications from seawater to soil. Tubular Anodes are available in a number of diameters, lengths, current carrying capacities and life ratings.

MMO tubular anode can be in single or in string, it is generally adopting titanium tubular as substrates and coated with a mixed metal oxide catalyst.

Mixed metal oxide based electrocatalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current..

Benefits of MMO Coated Tubular String:

· Lightweight/Durable

· High current output

· Low cost

· Dimensionally stable

· High cost performance

The specification of the below displayed MMO Coated Titanium Tubular String Anode

|

Material

|

Titanium

|

|

Coating

|

MMO

|

|

Country of origin

|

India

|

|

Thickness

|

0.9 mm

|

|

OD

|

25.4 mm

|

|

Length

|

500 mm

|

Cathodic protection is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. A simple method of protection connects the metal to be protected to a more easily corroded "sacrificial metal" to act as the anode.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

c2437e51-369e-48b1-b64a-29a4318cedb5|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

July 15, 2022 12:42 by

admin

adminCorrosion is naturally a destructive process that occurs when some metals are exposed to the environment and occurs when reaction between air, moisture and the metal gives rise. It commonly occurs in iron-based metals, steels etc. There are different methods to prevent and control corrosion. One of the best known method is Cathodic Protection.

Cathodic protection is one of the main technique to prevent corrosion. Cathodic protection is of two types they are Impressed Current Cathodic Protection (ICCP) and Galvanic Protection also known as DCCP. Cathodic protection systems protects a wide range of metallic structures in various environments.

Titanium is highly resistant to chemical attack and has the most elevated solidarity to weight proportion of any metal. These unique properties make Titanium reasonable for a large number of utilizations. It's firmness to weight proportion as steel is like steel meaning it can be used as a substitute where weight is an important consideration.

Follow us on:

Pinterest, Instagram, Facebook, Twitter

69abe517-c1d9-4374-b3bc-b4051d1c95a1|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

June 16, 2022 11:46 by

admin

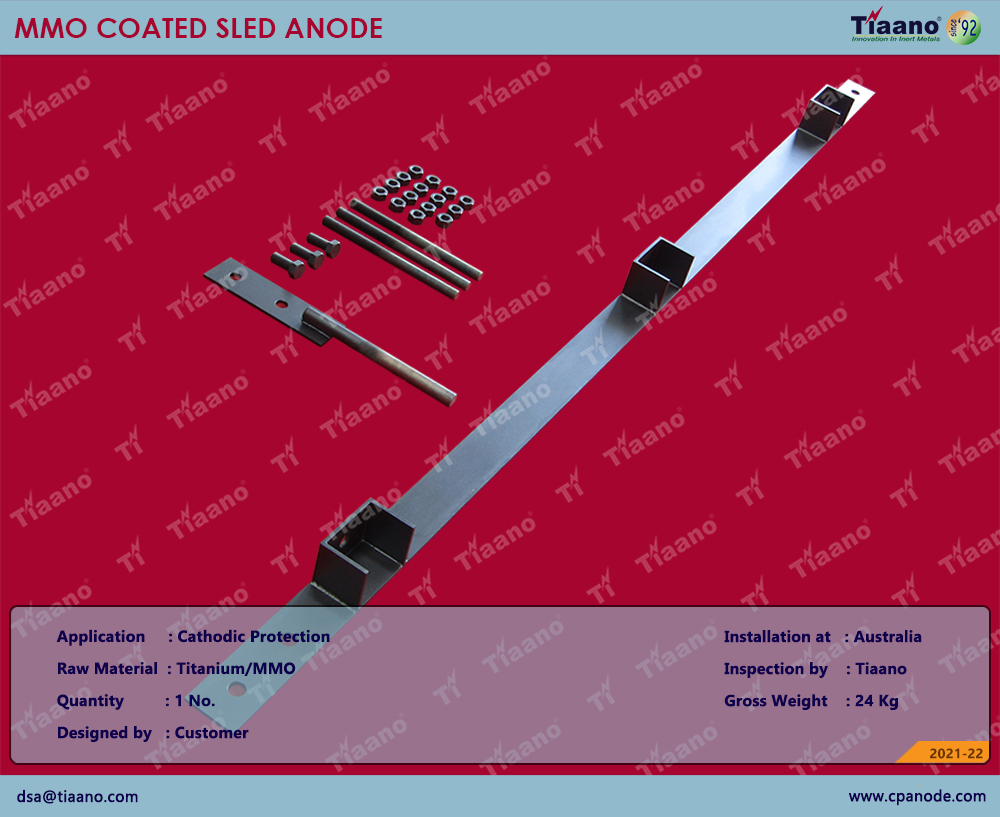

adminAnode sled systems are made to provide cathodic protection solutions to many types of offshore structures such as platforms, piers, wharfs, pilings or even pipelines.

The huge issue which frequently uncovered of substantial construction like pier heaps in seawater is consistently consumed which we can't stop. Consumption on the metal coming about decrease in strength which prompts diminish the life. We can keep away from these consumption by ICCP (Impressed Current Cathodic Protection).

To keep away from more noteworthy misfortunes because of sea water corrosion, it required a security against consumption on the point of support. One strategy accessibility is to introduce the cover or much known as heaps jacketing which will be conciliatory sort. However, we can involve MMO Anodes for these assurance.

The most impacted by the presentation is on the mainstays of the impacted sprinkles water zone or cited. At the sprinkle zone, the design steady sprinkles of ocean water, and consequently we expected to give the ensuing solidarity to the anodes, since the anode isn't containing a lot of weight.

In this manner, substantial construction like sled anodewill be utilized. So the anode will be in that position where the breakwater heap getting secured. These anodes are significantly endure over 20 years.

Follow us on:

Pinterest, Instagram, Facebook, Twitter

7a02eaab-cbfa-49e6-bd06-0cb375cd2051|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

June 16, 2022 11:40 by

admin

adminZinc Reference electrodes are generally implemented for the purpose of monitoring the anode in cathodic protection of buried or immersed metallic structures. It is made of high-purity Zinc alloy, ensuring accuracy and stability of potential measurements. The electrode frame is made of stainless steel, coated carbon steel or Rubber. The electrode can be designed to fix in the structure. By means of specifically designed supports.

These Zinc Reference Electrode implements a major usage in the cathodic protection System. Zinc reference Electrode are in different shapes like disc, rod and strip with different dimension, which is also installed in the Heat exchanger to monitor the current supply of Cantilever anodes.

Follow us on:

Pinterest, Instagram, Facebook, Twitter

9d93ceaa-27d3-4479-977f-3e9901facd8e|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

June 16, 2022 11:20 by

admin

adminPlatinum is an excellent catalyst because of its high conductivity and low utilization rate. Platinum deposition made by electroplating strategy over a high corrosion resistance substrate (Titanium). Since Titanium substrate is having non-destructive nature structure by protecting oxide film by platinum plantings.

Platinized cantilever anode is utilized for safeguarding pipeline internals, pull and condenser box inner for a long time and more by applying DC current with transformer rectifier. Ordinarily titanium is notable for its high protection from erosion both water and chemical media but titanium is the poor electricity conductor. So we use platinum/MMO plating/coating to expand the conductivity.

Advantages:

- Low consumption rate that conserves precious platinum.

- Favourable dimensional stability.

- Corrosion resistance ensures durability with easy maintainability.

- Light weight, as well as favourable current distribution in electroplating.

Tiaano manufacturing and supplying various anodes for cathodic production based on titanium, niobium and other exotic metals. We produce a wide variety of standard and customized anode shapes to maximize your benefit.

0e238642-7354-4b0a-a5f0-5c7cc783686f|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

June 9, 2022 10:41 by

admin

adminStrip anode is mostly utilized for the erosion insurance of seawater structure, Pilings, Piers, Jetties and drifting vessels and so on. Normally these anodes are utilized in the security of Seawater Application. Strip anode is a vital part for Cathodic Protection frameworks in seawater structures. It is made out of a valuable metal blended oxide impetus in the titanium plates by warm cycle.

Titanium strip anodes are fabricated utilizing titanium ASTM B 265 Gr. 1 or 2, Coated with Platinum bunch valuable metal blended oxide covering. MMO covering comprises of Ir and Ta and it is appropriate for use in all cathodic assurance applications. Since blended metal oxide anodes have a very low utilization rate, the titanium substrate stays consistent over the plan lifetime of the anode.

The leading anti-corrosion & uniform current distribution characters, it have great physical and mechanical properties of titanium. MMO covered anodes are emphatically suggested for Impressed Current Cathodic Protection (ICCP) application. We likewise fabricated and provided FRP Insulated Strip anode for different clients.

1f02bc22-b86f-4ab8-98f2-8b3e9cb0bed5|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

June 9, 2022 10:36 by

admin

adminImpressed Current Cathodic Protection frameworks are a definitive answer for all erosion issues to safeguard the metallic design for long time and are perceived as a better option than conciliatory anode frameworks which require successive substitution. Intrigued current cathodic security frameworks are liked by transport proprietors since they decrease fuel cost and support.

MMO/Platinised Disc, Elliptical and Strip Anodes are grown explicitly for security of Dam and Navigation lock entryways. Since our disc, elliptical & strip anodes are intended to work in new, saline and seawater conditions - utilized in other appropriate applications incorporates marine designs, water tanks and vessels. With a discretionary essential seal spacer gasket, it very well may be utilized within pipes, siphons, water tanks or other bended surfaces as well.

Disc anodes can be installed in dividers of boat bodies, condenser/water box, siphon inward/outside attractions and release to safeguard for longer years. It will be protected with rubber treated form to safeguard from disintegration. While utilizing MMO covered rubber treated plate anode to safeguard the boat structure from ocean water consumption, outside flow are applied to change over high expected anodic locales on a boat frames to low-likely cathodic destinations This ensures that ship hull surface is protected from corrosion.

Follow us on:

Pinterest, Instagram, Facebook, Twitter

03fe1031-d2ae-4907-8009-b2e8cb800944|0|.0|27604f05-86ad-47ef-9e05-950bb762570c