What is Cathodic Protection?

Cathodic protection system is to protect a wide range of metallic structures in various environments. Common applications or environment to protect steel, water or fuel pipelines and steel storage tanks such as huge oil tanks, chemical storage tanks, steel pier piles, ship and boat hulls, offshore oil platforms and onshore oil well casings and metal reinforcement bars in concrete buildings and structures. Corrosion can be defined as degradation of metal by forming electrical circuit where electrons get exchanged.

Ti Anode Fabricators Pvt. Ltd,Chennai, India is one of the best manufacturer in making MMO anodes or mixed metal oxide Cathodic Protection anodes and reference electrodes for a full range of cathodic protection application, by using Impressed Current Cathodic Protection (ICCP) process. The principle of cathodic protection is to connect an external anode to the metal and passing an electrical DC current so that all areas of the metal surface become cathodic and therefore do not corrode.

The external anode is to be an impressed current cathodic protection anode, where the current is impressed from an external DC power source. DC current is sent through an insulated wire to the anodes [which are either Dimensionally stable anodes / dimensionally stable anodes - MMO coated titanium anodes, Platinised titanium anodes, Platinized niobium anodes or their copper cored with platinum plated surface] buried in the soil like underground storage tank, pipeline, ship hulls etc.

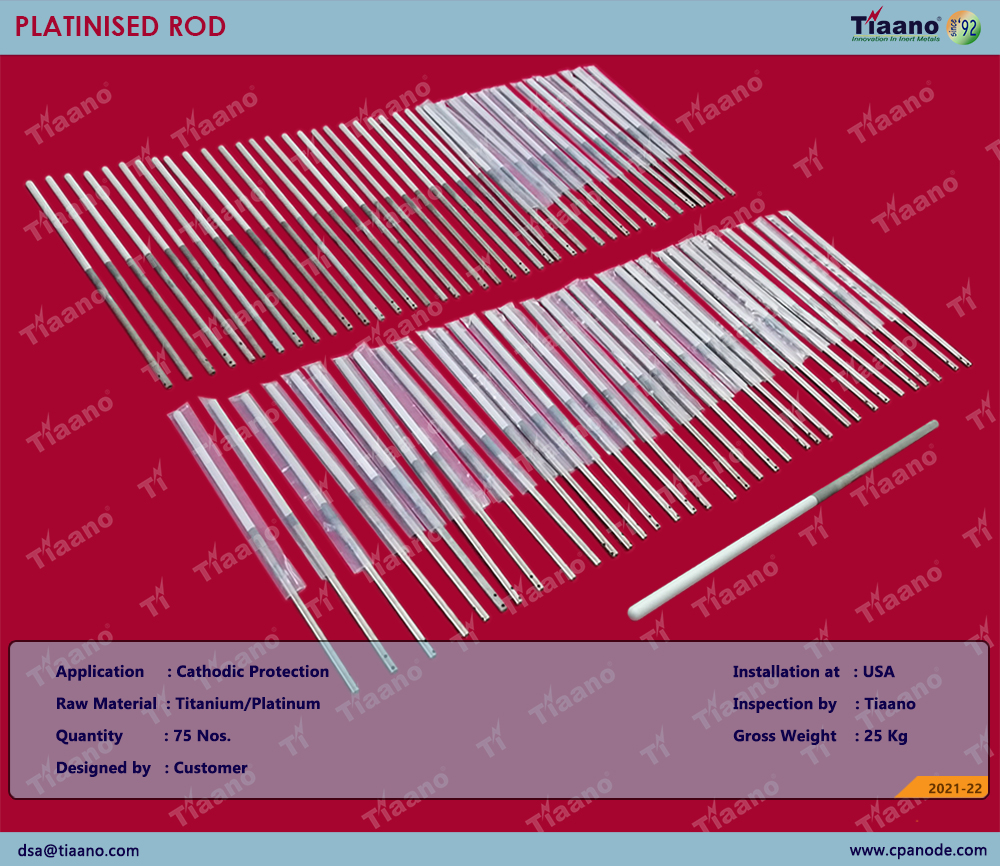

Platinised Titanium Anode:

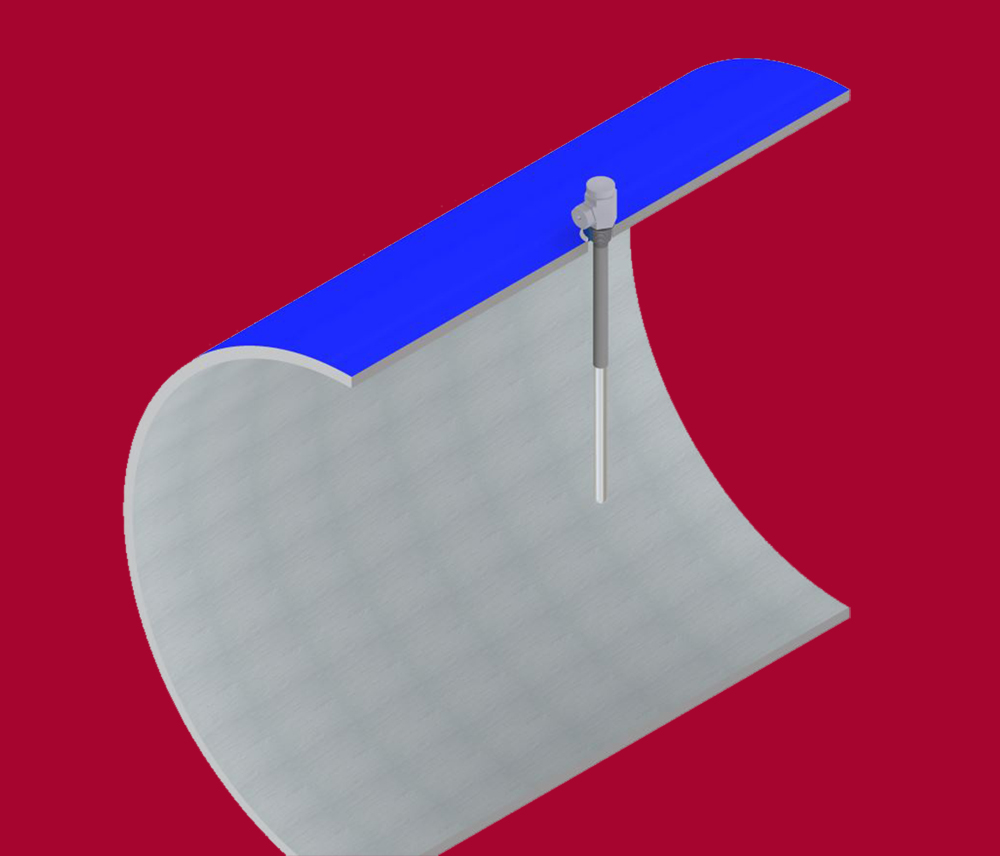

A platinized titanium anode is simply a titanium anode coated with platinum. These anodes act as an inert anodes and are non-consumable and long lasting. These anodes are insoluble in electrolyte where electrolysis is present. Platinized Titanium Rod are usually used in cantilever anode which is used for protecting pipeline internal, pump internal & condenser box internal for 30 years and more by applying DC current with transformer rectifier.

Applications:

- Deep & conventional ground beds.

- Jetties in fresh, brackish and salt-water electrolytes.

- Water tanks.

- Lock Gates.

- Intake Screens.

- Marine application.

Tiaano’s different types of anodes for Cathodic Protection:

Platinum plating and MMO coating have long life in all environments and services and also withstand in natural waters. Tiaano design and manufacture various types of anodes such as:

- Strip/Disc Anode

- Ribbon mesh anode

- Tubular String Anode

- Canister/Cantilever anodes

- Piggy back anodes

- Cables etc.

We also supply anodes for electroplating, electrolysis, water treatment deionization and various applications.

For more details visit these links:

www.cpanode.com,www.tiaanostore.in,www.tiaano.com

Follow us on:

Pinterest, Instagram, Facebook, Twitter