July 21, 2022 18:09 by

admin

admin

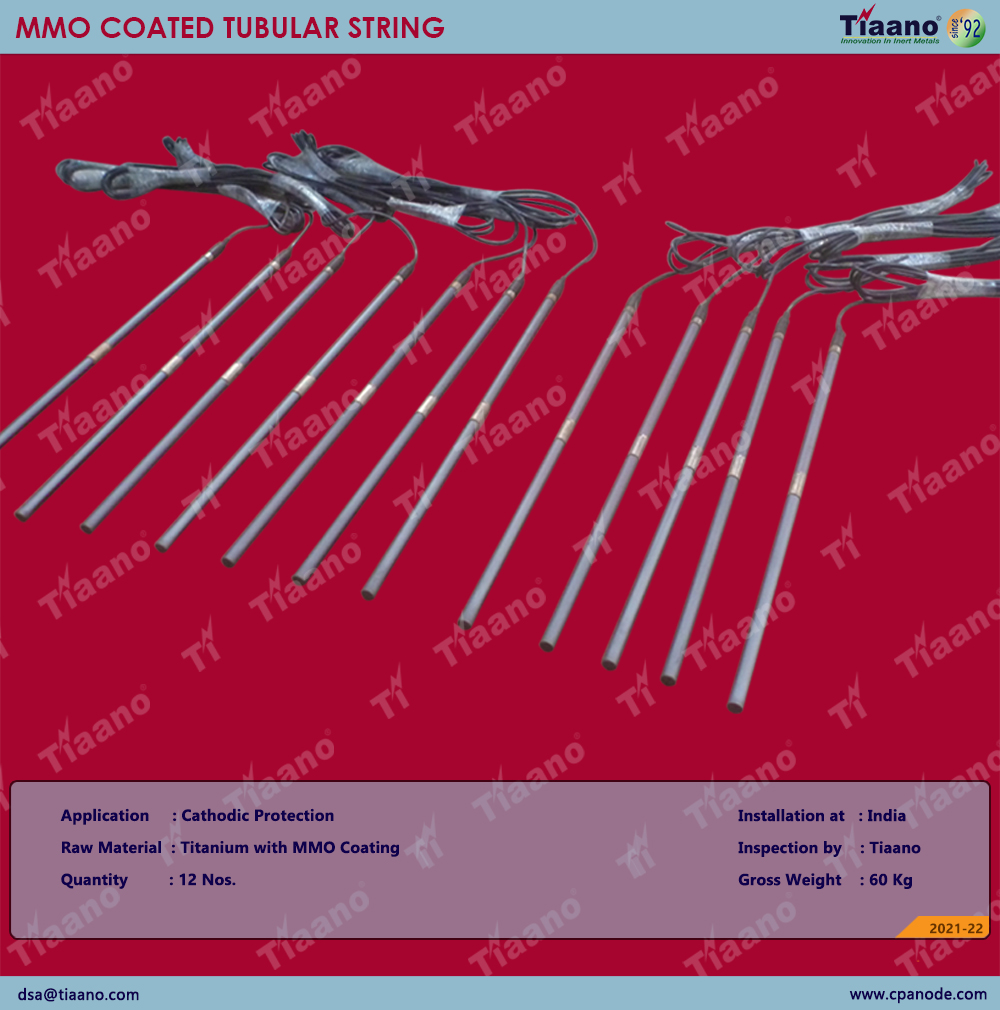

MMO Coated Tubular String for Cathodic Protection

We Tiaano do fabrication & supply of MMO Titanium tubular anodes by using titanium seamless tube and coated with platinum group precious metal mixed oxide coating. Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements

Mixed Metal Oxide Coated Titanium anode design for the demands of deep anode beds, shallow beds and the earth’s natural waters. MMO Tubular anodes are dimensionally stable anodes which remain constant throughout all of the anode life, thus providing a constant performance with a low resistivity MMO Titanium tubular anodes are a titanium tube base with a mixed metal oxide conductive coating and itself an excellent electronic conductor.

The design life of the anode varies with operating current in a variety of applications from seawater to soil. Tubular Anodes are available in a number of diameters, lengths, current carrying capacities and life ratings.

MMO tubular anode can be in single or in string, it is generally adopting titanium tubular as substrates and coated with a mixed metal oxide catalyst.

Mixed metal oxide based electrocatalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current..

Benefits of MMO Coated Tubular String:

· Lightweight/Durable

· High current output

· Low cost

· Dimensionally stable

· High cost performance

The specification of the below displayed MMO Coated Titanium Tubular String Anode

|

Material

|

Titanium

|

|

Coating

|

MMO

|

|

Country of origin

|

India

|

|

Thickness

|

0.9 mm

|

|

OD

|

25.4 mm

|

|

Length

|

500 mm

|

Cathodic protection is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. A simple method of protection connects the metal to be protected to a more easily corroded "sacrificial metal" to act as the anode.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

c2437e51-369e-48b1-b64a-29a4318cedb5|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

February 16, 2022 10:55 by

admin

adminPlatinized Titanium anodes take advantage of the low consumption rate and high current density. Voltages in excess of 10 Volts will result in severe pitting of the titanium core causing premature failure. Exterior protection of ships hulls - anodes in the shape of plates, discs or strips. Platinum is a least reactive metals that has remarkable resistance to corrosion, even at high temperatures.

The principle of cathodic protection is connecting an external anode to the metal to be protected and the passing of an electrical DC current so that all areas of the metal surface become cathodic and therefore do not corrode. DC current is sent through an insulated wire to the anodes buried in the soil near the articles like underground storage tank, pipeline & etc.

Platinized FRP insulated strip Anode with impressed current leads to protect the hull of the ships. Negative terminal which is connected to ship hull and positive terminal with impressed current anodes. Underwater steel structures protection like wharves, jetties, sheet pile walls and piers. Usually rod type anodes are distributed throughout the structure for protection and to give a good current distribution.

Advantages:

- Increases life of rudders, shafts, struts and propellers.

- Anodes are light and compact for easy shipping, storage and installation.

- High current efficiency.

- High anti-corrosion property & lasting working life.

For more details visit these links:

www.cpanode.com,www.tiaanostore.in,www.tiaano.com

Follow us on:

Pinterest, Instagram, Facebook, Twitter

c02fdeee-b7cb-44b7-8695-0d4533652325|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

May 13, 2021 11:53 by

admin

adminMMO (Mixed Metal Oxide) coated rubberized disc anodes are used to protect the ship or hull from sea water corrosion. Normally Titanium having noncorrosive, but it contains nonconductive material. MMO coated will give the conductivity in titanium as per the application and amperage. Zinc reference electrode will be placed in particular distance as per the cathodic protection system to monitor the conductivity of the MMO coating disc.

Sea water is very corrosive environment because the salt present in it makes very good conductor of electricity. It creates a lot of free irons which accelerate oxidation of iron (mid steel) which made of oxidation.

When using MMO coated rubberized disc anode to protect the ship hull from sea water corrosion, external current are applied to convert high-potential anodic sites on a ship hulls to low-potential cathodic sites. This ensures the ship hull surface is protected from corrosion.

We can install MMO coated disc in the hull by passing DC current by a rectifier which will protect the ships life longer nearly 20 to 25 years depends upon the usage of the ship which afloat often.

MMO coated rubberized disc size well be customized depends upon the design of the CP system.

Advantages:

- Ø Durability compared to galvanic anode.

- Ø Demonstrate reliability.

- Ø Optimum documented corrosion production at minimum overall cost.

- Ø Anodes are lite, sturdy and compact for easy shipping, storage and installation.

Tianno manufacturing platinum as well as MMO coated disc anodes. Below product recently supplied to Singapore.

e52c2ae9-37ae-4399-b114-065fbc568553|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

May 10, 2021 16:35 by

admin

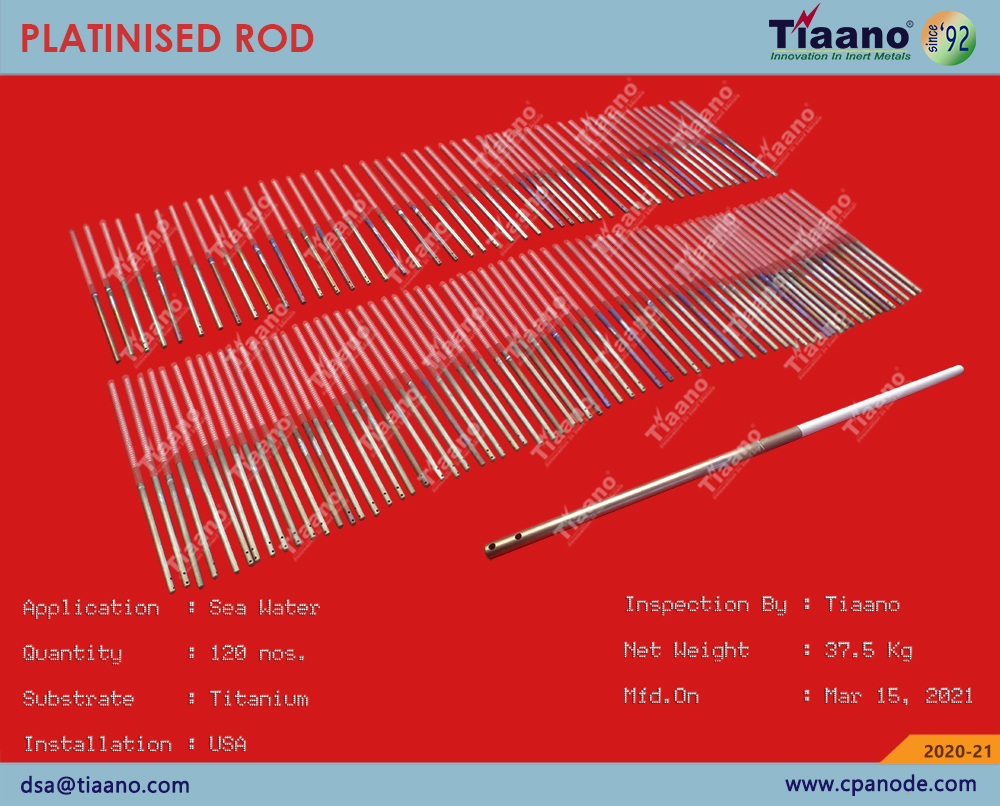

adminPlatinized rod used in cantiliver anodes with active part of plating to protect the gigantic pump internals, suction, condenser box and pipelines etc.,

Platinum is an excellent catalyst due to its high conductivity and low consumption rate. Platinum deposition made by electroplating method over a high corrosion resistance substrate (Titanium). Since Titanium substrates is having non-corrosive nature form by insulating oxide film by platinum plantings.

Platinized titanium rod are usually used in cantilever anode which is used for protecting pipeline internals, suction and condenser box internal for 30 years and more by applying DC current with transformer rectifier. Normally titanium is well known for its high resistance to corrosion both water and chemical media but titanium is the poor electricity conductor. So we use platinum/ MMO plating/ Coating to increase the conductivity.

Advantages:

- Ø Low consumption rate that conserves precious platinum.

- Ø Favorable dimensional stability.

- Ø Corrosion resistance ensures durability with easy maintainability of the cathode to be protects.

- Ø Light weight, as well as favorable current distribution in electroplating.

Tianno (Ti Anode Fabricators Pvt Ltd, Chennai, India) manufacturing and supplying platinized anodes and cathodic production based on titanium, niobium and other exotic metals. We produce a wide variety of standard and customized anode shapes to maximize your benefit. Below product is recently supplied to Saudi Arabia.

d9eee310-cdef-43a9-959d-7dcb46ce2fb9|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

March 20, 2021 13:37 by

admin

adminPlatinised rod is used for cantiliver anodes with active part of platinum plating to protect the gigantic pump internals and pipe lines.

Tianno manufacturing FRP insulated platinised rod and MMO coated rod for the cathodic protection of these structures. Below photo image of recently supplied to USA.

8167afe7-d515-4b8f-aae1-7b21c9853f3f|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

March 13, 2021 16:30 by

admin

adminFor the protection of ship or boat hull from seawater corrosion, we need to insert our MMO Coated titanium disc or Niobium disc or Platinized rubberized disc.

04c52f29-0d50-437e-a452-af96e67faf2d|0|.0|27604f05-86ad-47ef-9e05-950bb762570c