November 13, 2019 12:12 by

admin

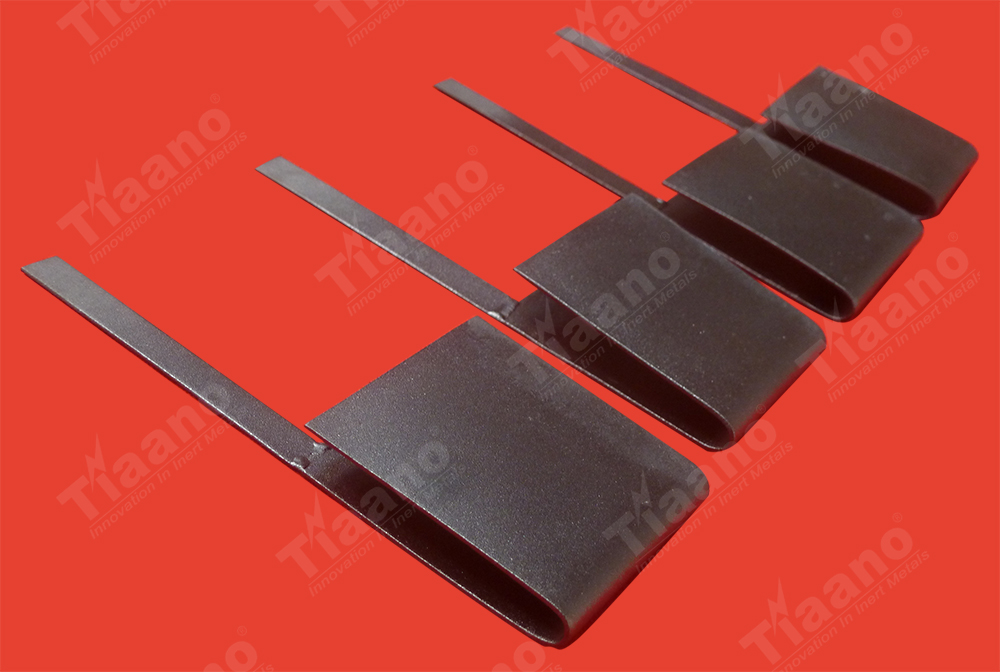

adminMMO COATED DSA PLATES for electro oxidation to treat the water

In recent years, there has been increasing interest in finding innovative solutions for the

efficient removal of contaminants from water, soil and air. Government also insist the industries to make a zero discharge and chemical contamination free to protect our environment.

ELECTRO OXIDATION AND ELECTRO COAGULATION process together treats the water as a disinfection using our MMO coated plates with the catalyst of Ruthenium Oxide (RuO2).

Treatment of a low BOD COD ratio landfill leachate was conducted by means of electro chemical oxidation process. Electrochemical oxidation process is effective in removing pollutants from landfill leachate.

Electro-oxidation (EO), also known as anodic oxidation, is a technique used for wastewater treatment, mainly for industrial effluent playing roll in advanced oxidation process. The most general layout comprises two electrodes, operating as anode and cathode, connected to a power source.

Electro-oxidation is an excellent and eco-friendly technique for the removal of persistent organic contaminants, electrochemical advanced oxidation processes are ordinarily used to remove COD and BOD presence in the water. However, this technique suffers the primary disadvantage of high energy consumption and low current efficiency.

Tiaano supplying the ELECTRO OXIDATION AND ELECTRO COAGULATION systems. Also we are supplying the MMO Coated plates (titanium) used in the system.

We, the Ti Anode Fabricators private limited, chennai supplying different types of MMO (mixed metal oxide)Coated plates for Water oxidation.

MMO Coated PLATES :

f094b22b-8f44-406f-bb7f-45724c83fafa|1|5.0|27604f05-86ad-47ef-9e05-950bb762570c