August 1, 2022 12:07 by

admin

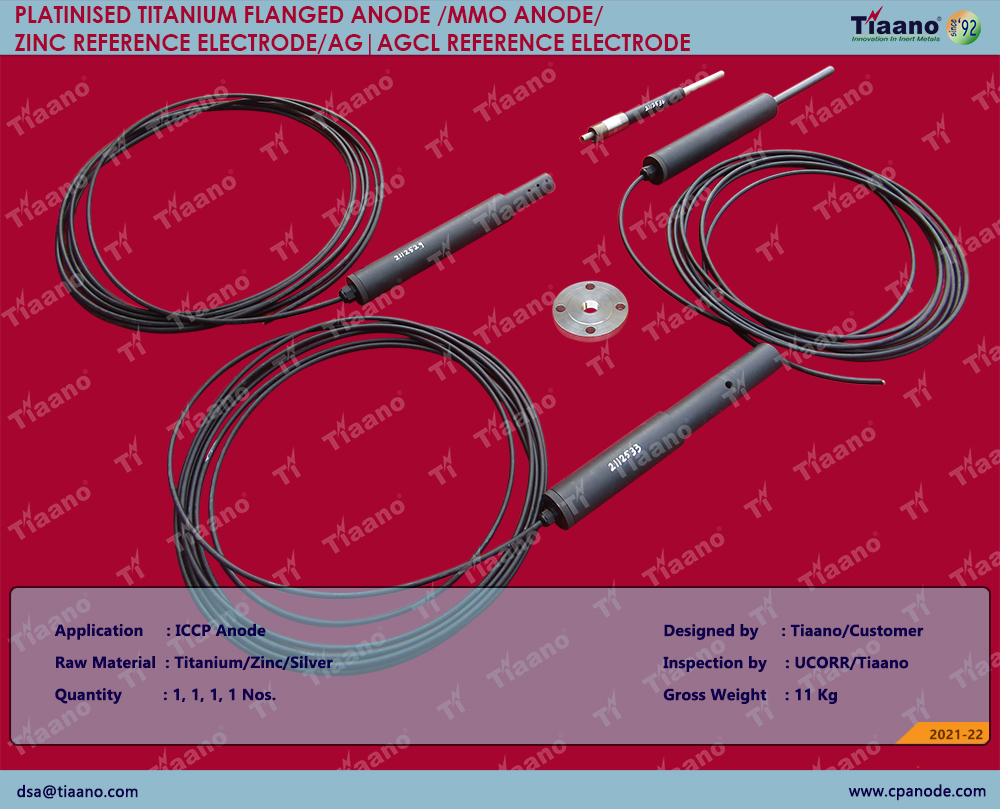

adminThe use of a metal reference electrode to measure potential difference in direct contact with the electrolyte around the structure may not make sense, but the reference zinc electrode in seawater is suitable for many applications. Successful samples have also been observed in the use of this electrode in the tanks bottom with the backfill, although many designs today use copper/ copper sulphate reference electrodes.

Zinc reference electrode is cheaper than silver/ silver chloride reference electrode and is used instead unless a high degree of stability is required. In addition, the mechanical stability of this type of electrode is much higher than other reference electrodes which have different and fragile components

High purity zinc ingots (minimum 99.9% with maximum iron content of 0.0014%) are used in the production of zinc reference electrodes. For connecting, a copper cable with chloride resistance coating and with 10 mm2 or 16 mm2 cross section is used and the cable is welded to the steel core inside the electrode. The interface between the copper cable and the steel rod is coated with epoxy resin.

MMO Coated cantilever anode are used to protect the surface of gigantic pump internals and condenser box where the sea water pass through in it. These anodes are use to protect the pump internals from erosion and corrosion with impressed current.

Reference electrodes are used in locations where a constant, stable reference where our anodes are installed with constant potential rectifiers.

Normally we can use wide variety of reference electrodes like zinc, silver chloride or copper sulfate reference electrodes for pump internal, condenser water box/vessel applications to monitor the cathodic protection anodes activeness.

Tiaano supplying MMO & platinum plated cantilever anodes and zinc reference electrodes for cathodic protection.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

5c067b6d-5ad4-430d-a1cf-4ef5fbb2d5be|0|.0|27604f05-86ad-47ef-9e05-950bb762570c