May 8, 2023 11:19 by

admin

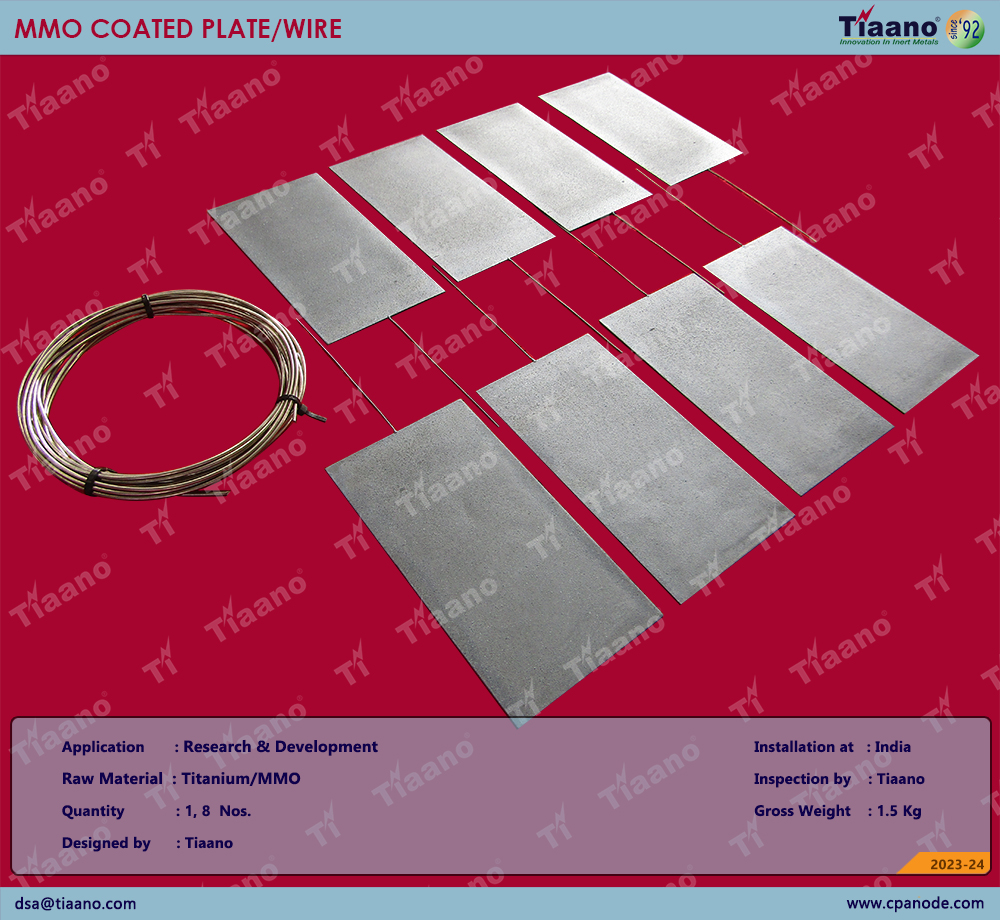

adminMMO coated anodes are widely used in various industries because it has special physical and chemical properties like high corrosion resistance, catalytic in nature and thermal conductivity.

MMO titanium anodes act as inert anodes and are non-consumable and long lasting. Ti's MMO coating has proven superior to other mixed metal oxide coatings currently being used.

Research and development (R&D) includes activities that companies undertake to innovate and introduce new products.

MMO coated titanium wire anode is suitable for direct burial in fine sand, carbonaceous backfill or immersion in fresh or saline waters. MMO-Ti wire anode can be connected to a feed cable at one end or ‘piggybacked’ to form a continuous anode suitable for installation under storage tanks or to provide continuous close protection for pipelines.

Wire anodes can also be used to protect the internal surfaces of water tanks where their malleable shape permits even current distribution in areas where there can be large variations in water level.

e2f97e4c-c930-4489-8508-2334932bd77f|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

July 30, 2022 12:07 by

admin

adminTiaano is pioneer in Design, Fabrication of Different types of Anode. Most of the Anodes’ MOC (Material of Construction) is Titanium. There is a MMO (Mixed Metal Oxide) coating over the Titanium becomes Anode, which will be called as MMO coated Plates. These Anodes have been supplied as large quantity to many of our customers.

There are as many types of anode compositions as there are applications. Platinized Titanium, Iridium Coated Titanium and Platinised Niobium Electroplating anodes offer numerous benefits of Electro Plating Industry.

Electroplating is used to coat certain metals with a thin layer of industries for coating metal objects with a thin layer of a different metal. This electrochemical of a pure metal, like silver or gold, copper, zinc or any of several alloys. During the process, an electric current passes through a solution known as an electrolyte. The composition of the electrolyte depends on the desired coating. The item being electroplated (cathode) is immersed into the electrolyte solution, as is the plating / coating anode.

The two are then connected to an electrical current source, by connecting the positive end to the plating anode and the negative to the item being to be plated. Once current flows through the system positively charged metal ions become attracted to the negatively charged item, thereby coating the item with the desired finish.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

98d25fef-894d-43ab-84ef-6bb18cdd6d71|0|.0|27604f05-86ad-47ef-9e05-950bb762570c