Platinised Titanium Rod supply to Korea (South) for Cathodic Protection Application

Platinized Titanium anodes are widely used for various applications including Impressed Current Cathodic Protection (ICCP) such as hard chrome plating, metal electroplating, electronics, semiconductor industry, chemical process engineering, electroplating, electro dialysis, electroforming (Conforming anodes), electrochemical sensing, electro winning and metal refining, electrolytic regeneration of chromic acid, sodium hypochlorite production, Electro synthesis of organic and inorganic chemicals Etc.,

This platinized titanium anode are highly competent to survive the atmosphere whereas high chemical and environmental corrosion risk exist such as.

v Deep & conventional ground beds.

v Jetties in fresh, brackish and salt-water electrolytes.

v Water tanks.

v Lock Gates.

v Intake Screens.

v Marine application.

Surface resistance of Platinized titanium anodes are very less by nature while compare conventional electrodes, so power efficiency of an entire process become superior.

Platinum layer on titanium substrate become stable during an entire design life, so this anodes are also known Dimensionally Stable Anode.

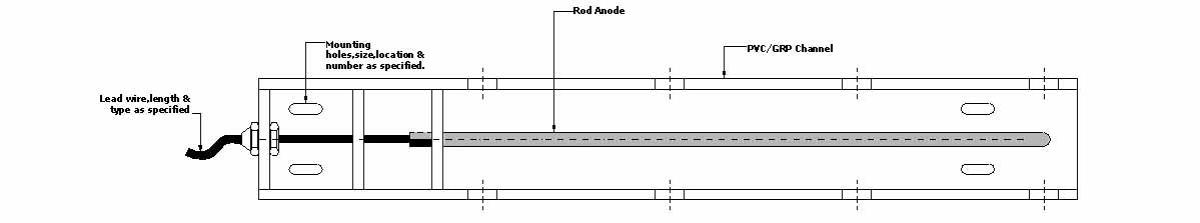

Platinized titanium anodes are manufactured with a titanium base structure, in the form of either plate, rod, wire, mesh or tube (or any shape as per request). Catalyst thick on surface: Platinum (in micron thick) 2.5 to 7.5; MMO (in micron thick) 8.0 to 10.0.

Advantages

v Excellent corrosion resistance and catalytic activity

v Low hydrogen evolution potential, can be utilized as both an anode and cathode

v Great current efficiency

v Reversible polarity

v Excellent coating adhesion

Current Output: Current output is dependent on…

A] Coating catalyst

B] Wire size

C] Coating thickness

D] Substrate

E] Application

F] Design life

G] Temperature.

Anodes are available with the current output of 1.7 A to 13 A/each. Or the operational CD is over 50A / ft2. Anode Size: Available in six standard sizes of rod anodes as follows, 3.0 mm dia; 6.0 mm dia; 10.0 mm dia; 12.0 mm dia; 20.0 mm dia; 25.0 mm dia. Other sizes are available on request.