August 22, 2022 12:54 by

admin

adminPlatinum titanium is a platinum metal oxide or platinum layer-coated on a titanium substrate. It is non-consumption, durable, and insoluble in the electrolyte. We can use platinum titanium anode for cathodic protection and electroplating.

Zinc Reference electrodes are generally implemented for the purpose of monitoring the anode in cathodic protection of buried or immersed metallic structures. It is made of high-purity Zinc alloy, ensuring accuracy and stability of potential measurements.

The electrode frame is made of stainless steel, coated carbon steel or Rubber. The electrode can be designed to fix in the structure. By means of specifically designed supports.

Ag/Agcl Reference Electrode is the silver/silver chloride reference electrode is composed of a silver wire, sometimes coated with a layer of solid silver chloride, immersed in a solution that is saturated with patassium chloride and silver chloride.

The Reference Electrode implements a major usage in the cathodic protection System. Reference Electrode are in different shapes like disc, rod and strip with different dimension, which is also installed in the Heat exchanger to monitor the current supply of Cantilever anodes.

- Flexibility to meet various user needs

- Produce complex shape of the anode

- Energy-saving

- Lightweight (especially the mesh grid anode)

- Longer working life under higher current density

- Firm titanium structure, less deformation

- Second platinized allowed;

- Uniform deposit, final products with high quality.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

ee10be0d-ddf1-4f33-97e4-a1b913433851|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 22, 2022 11:31 by

admin

admin

Platinized titanium anode by adopting a thermal decomposition process to get a dense wear-resistant layer of platinum coating. They can modify the anode surface to improve the adhesion of platinum and the uniformity of coating thickness.

Platinum titanium is a platinum metal oxide or platinum layer-coated on a titanium substrate. It is non-consumption, durable, and insoluble in the electrolyte. We can use platinum titanium anode for cathodic protection and electroplating.

Platinum is a highly valued metal, and it is widely used in jewelry, engines, and industrial machinery.

We can customize the anode with different shapes such as mesh, rod, sheet, tube to suit various application areas.

Platinized titanium anode has both high anti-corrosion qualities and excellent platinum electrochemical performance. It is more advantageous as compared to other lead anode and soluble electrodes.

- Flexibility to meet various user needs

- Produce complex shape of the anode

- Energy-saving

- Lightweight (especially the mesh grid anode)

- Longer working life under higher current density

- Firm titanium structure, less deformation

- Second platinized allowed

- Uniform deposit, final products with high quality

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

baa9877b-1d02-4fdd-9389-705928899130|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

July 27, 2022 17:29 by

admin

admin

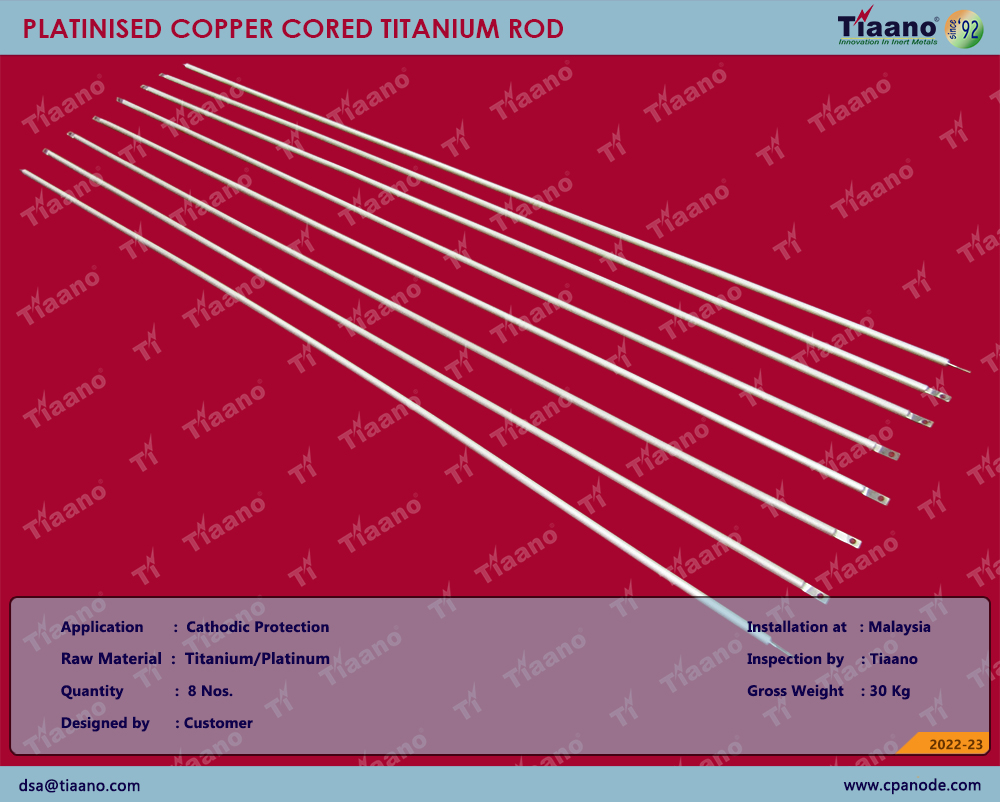

PLATINISED COPPER CORED TITANIUM ROD

Platinized titanium anodes are extensively used in electrolytic processes. They have successfully replaced lead anodes in electroplating applications due to their lower consumption, dimensional accuracy, ability to form precise deposit thicknesses on desired geometric shapes, predictable plating chemistry and ease of maintenance. These anodes can be designed and formed with various geometries based upon the parts to be electroplated.

Platinum on titanium anodes are highly preferred anodes for electrodeposition of copper, chromium, platinum, nickel, palladium and gold.

Platinized titanium anode by adopting thermal decomposition process to get a dense wear-resistant layer of platinum coating. The anode surface is modified to improve adhesion of platinum and to significantly improve uniformity of coating thickness, also reduce the coating porosity imparting greater acid resistance to the anode. This platinum coated titanium anode can be fabricated into bar, rod, sheet, mesh and other customized shape to meet your special needs.

Because of its high conductivity and low consumption rate, Platinum is an excellent anode material. Due to its high cost, Platinum is made practical for use by electroplating a thin layer over a high corrosion resistance substrate. Since Titanium, Niobium and Tantalum substrates have the ability to form an insulating oxide film under anodic conditions, they are commonly used as anode in ICCP (impressed current cathodic protection anode). Among them, Titanium is less expensive; however, it has a much lower breakdown potential than Niobium or Tantalum. The titanium oxide breaks down at anodic potentials in the 12 V range.

Advantages of platinized titanium anodes

Low consumption rate and high current density

Voltages in excess of 10 Volts will result in severe pitting of the titanium core causing premature failure

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

8730cea2-7309-4f2f-be20-436e3dc27e35|0|.0|27604f05-86ad-47ef-9e05-950bb762570c