August 7, 2023 02:45 by

admin

adminCorrosion is a natural process that converts a refined metal into a more chemically stable form such as oxide, hydroxide, carbonate or sulfide. It is the gradual destruction of materials by chemical or electrochemical reaction with their environment. Corrosion can be prevented by eliminating the oxygen or the positively charged hydrogen ions.

MMO coated tubular string anode are used to protect the pipe lines which is installed horizontal bed as well as vertical deep well with multi string /single string based on several design and field condition factors including current distribution requirements for different applications like Sea water, brackish water, sand etc.

These anodes connected to a DC power source, often a transformer-rectifier connected to AC power. In the absence of an AC supply, alternative power sources may be used, such as solar panels, wind power or gas powered thermoelectric generators. These tubular anodes are used to protect the pipelines from corrosion and rust.

Advantages:

- Lightweight/Durable

- High current output

- Low cost

- Dimensionally stable

- High cost performance

For Enquiries, please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

cea4574b-87c7-440c-97f9-4cc8d92e98ce|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

March 31, 2023 11:27 by

admin

admin

Tiaano MMO titanium tubular anodes are coated with mixed metal oxide that has an extremely low consumption rate measured in milligrams per year. Unlike other types of anodes the consumption rate of MMO anode is negligible with the dimensions of the anode element remaining virtually unchanged during the operational service life of the anode. As a result, the power required to impress current will remain the same.

Application

Marine structures, seawater intakes, deep well ground beds, horizontal ground beds, distributed anodes, tank internals & tank bottoms. Suitable for use in soils, mud, carbonaceous & petroleum coke backfill; fresh, brackish and sea-water.

8897fb4a-4191-4bb3-bd1c-c9e67321d7fd|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

March 30, 2023 16:26 by

admin

admin

Ti Anode Fabricators Pvt Ltd., manufactures CPCC Canister Anode with their in-house facilities in India, for Impressed current Cathodic protection application. Using following alternative anode combinations are been supplied based on the customer’s interest.

Titanium expanded mesh with Ti’s MMO coating.

Titanium wire with Ti’s MMO coating.

Titanium expanded mesh with Ti’s Platinum plating.

Titanium wire with Ti’s Platinum plating.

Niobium wire with Ti’s MMO coating.

Niobium wire with Ti’s Platinum plating.

Application:

Shallow vertical and horizontal surface ground beds.

Underground storage tanks.

Aboveground storage tanks.

Pipelines.

Advantages over Silicon - Iron anodes:

Twice the life

Unbreakable

Lighter weight

Easier to install

Narrower trench

Easy to centralize

Reduce excavation and drilling cost.

Material Of Construction:

Canister: Galvanized steel tube

Substrate: Titanium, ASTM B 265 or 348 Gr.1

Niobium, ASTM B

Catalyst: MMO or Pt

Cable: XLPE/PVC, EPR/CSPE, KYNAR/HMWPE.

Cable ~ anode connection: CPCC equal to LIDA.

ead9f4ae-97c1-41e7-aab0-2b678c11b30e|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

September 19, 2022 14:39 by

admin

adminTitanium tubular anodes are manufactured using titanium seamless tube and coated with platinum group precious metal mixed oxide coating. Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements

Mixed Metal Oxide Coated Titanium anode design for the demands of deep anode beds, shallow beds and the earth’s natural waters. MMO Tubular anodes are dimensionally stable anodes which remain constant throughout all of the anode life, thus providing a constant performance with a low resistivity

MMO Titanium tubular anodes are a titanium tube base with a mixed metal oxide conductive coating and itself an excellent electronic conductor.

The design life of the anode varies with operating current in a variety of applications from seawater to soil. Tubular Anodes are available in a number of diameters, lengths, current carrying capacities and life ratings.

MMO tubular anode can be in single or in string, it is generally adopting titanium tubular as substrates and coated with a mixed metal oxide catalyst.

Mixed metal oxide based electro catalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current.

Mixed Metal Oxide anodes are typically rated for a given output and life, for example 5 amps at 20 years. Within the normal range of current discharge for MMO anodes, this relationship is linear. The same 5 amp anode rated for 20 years of service would provide 40 years if only operated at 2.5 amps.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

cd06c6dc-a550-4319-8b3a-888c05a953e6|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

July 27, 2022 17:29 by

admin

admin

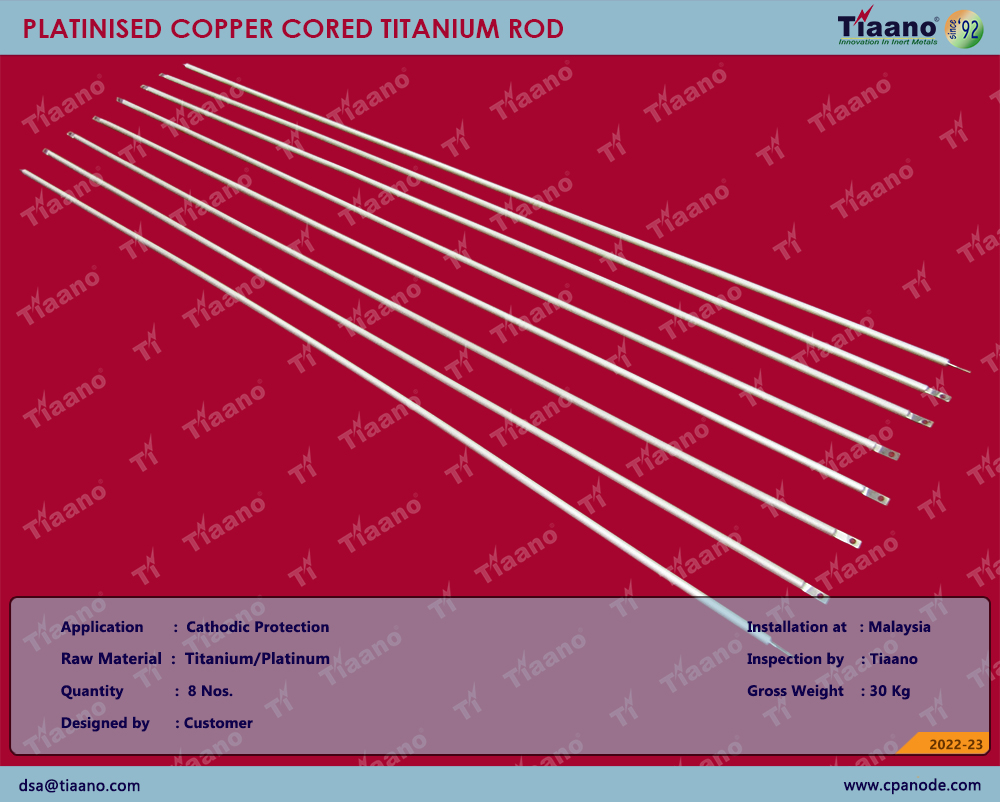

PLATINISED COPPER CORED TITANIUM ROD

Platinized titanium anodes are extensively used in electrolytic processes. They have successfully replaced lead anodes in electroplating applications due to their lower consumption, dimensional accuracy, ability to form precise deposit thicknesses on desired geometric shapes, predictable plating chemistry and ease of maintenance. These anodes can be designed and formed with various geometries based upon the parts to be electroplated.

Platinum on titanium anodes are highly preferred anodes for electrodeposition of copper, chromium, platinum, nickel, palladium and gold.

Platinized titanium anode by adopting thermal decomposition process to get a dense wear-resistant layer of platinum coating. The anode surface is modified to improve adhesion of platinum and to significantly improve uniformity of coating thickness, also reduce the coating porosity imparting greater acid resistance to the anode. This platinum coated titanium anode can be fabricated into bar, rod, sheet, mesh and other customized shape to meet your special needs.

Because of its high conductivity and low consumption rate, Platinum is an excellent anode material. Due to its high cost, Platinum is made practical for use by electroplating a thin layer over a high corrosion resistance substrate. Since Titanium, Niobium and Tantalum substrates have the ability to form an insulating oxide film under anodic conditions, they are commonly used as anode in ICCP (impressed current cathodic protection anode). Among them, Titanium is less expensive; however, it has a much lower breakdown potential than Niobium or Tantalum. The titanium oxide breaks down at anodic potentials in the 12 V range.

Advantages of platinized titanium anodes

Low consumption rate and high current density

Voltages in excess of 10 Volts will result in severe pitting of the titanium core causing premature failure

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

8730cea2-7309-4f2f-be20-436e3dc27e35|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

July 21, 2022 18:09 by

admin

admin

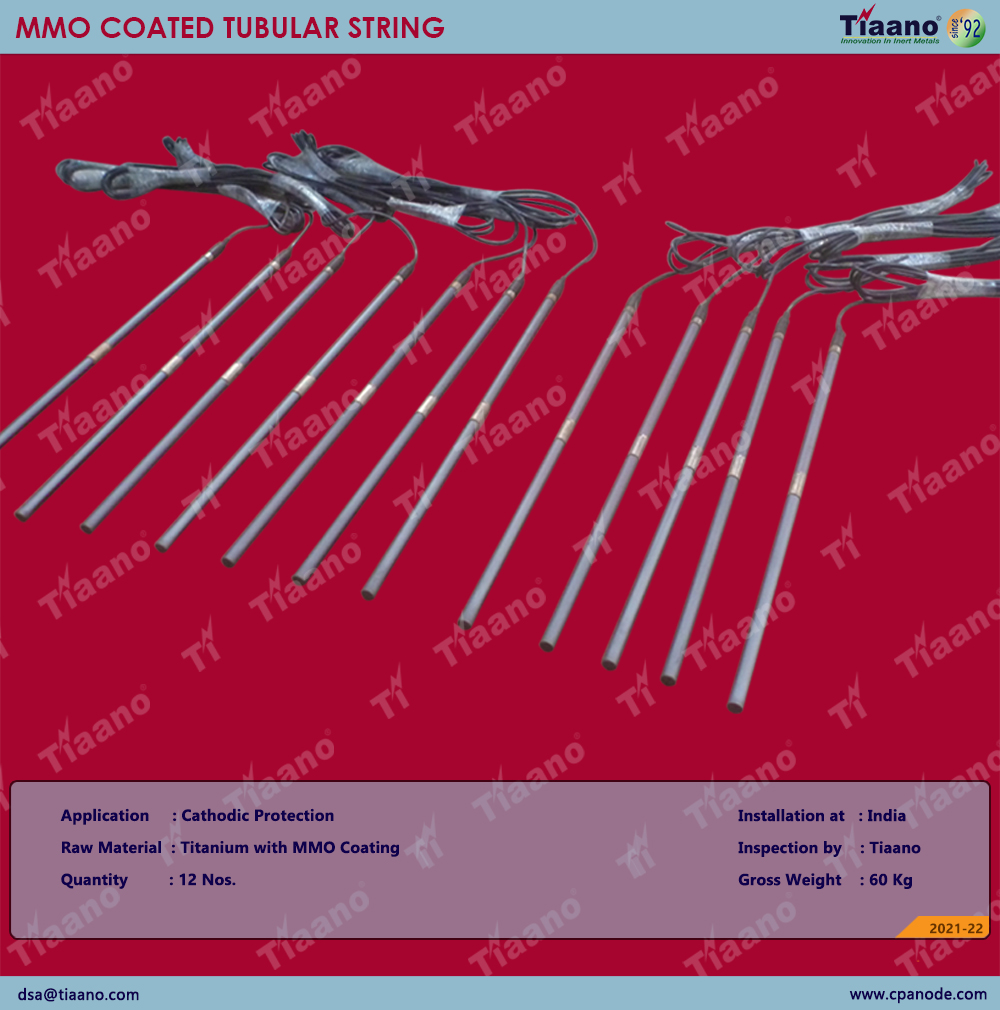

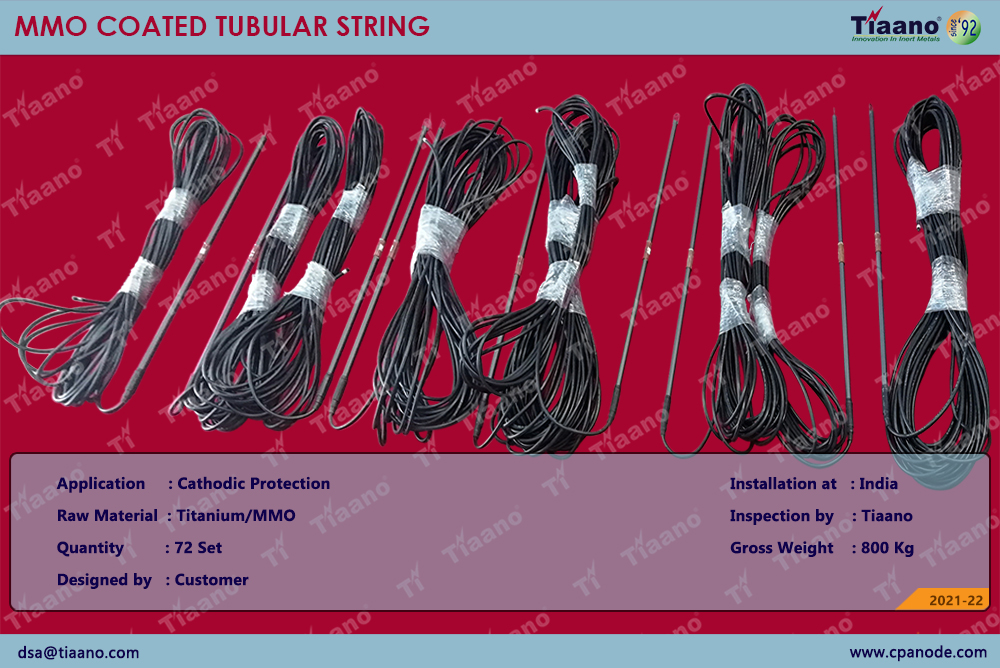

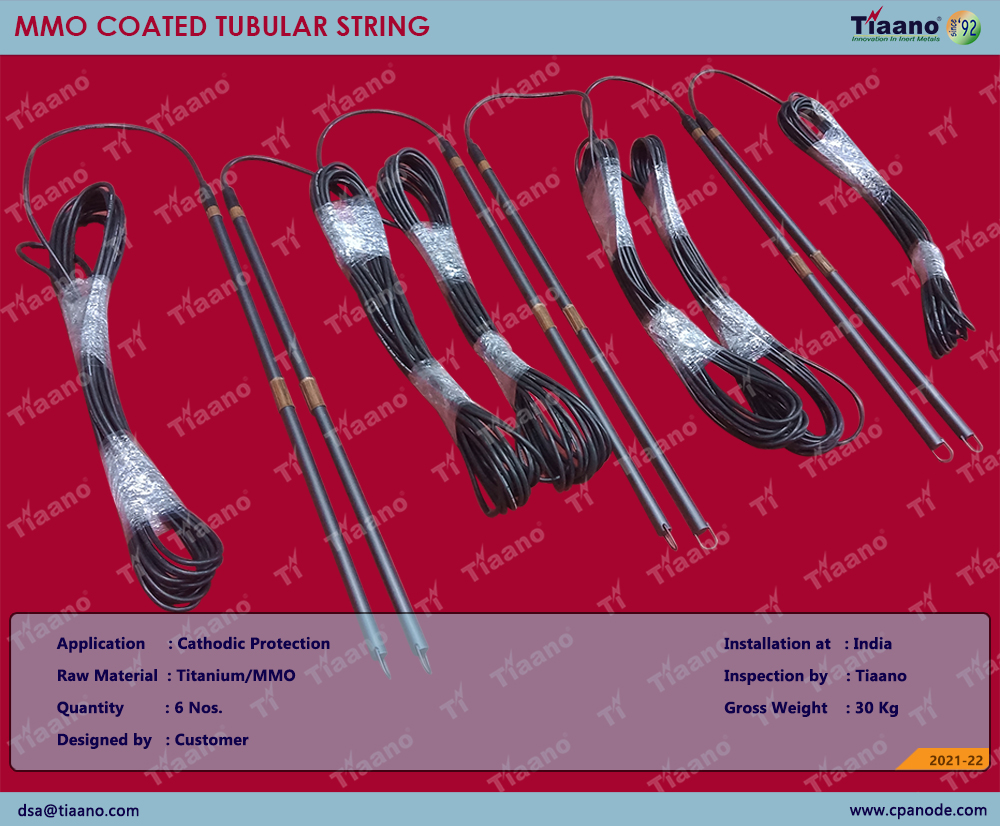

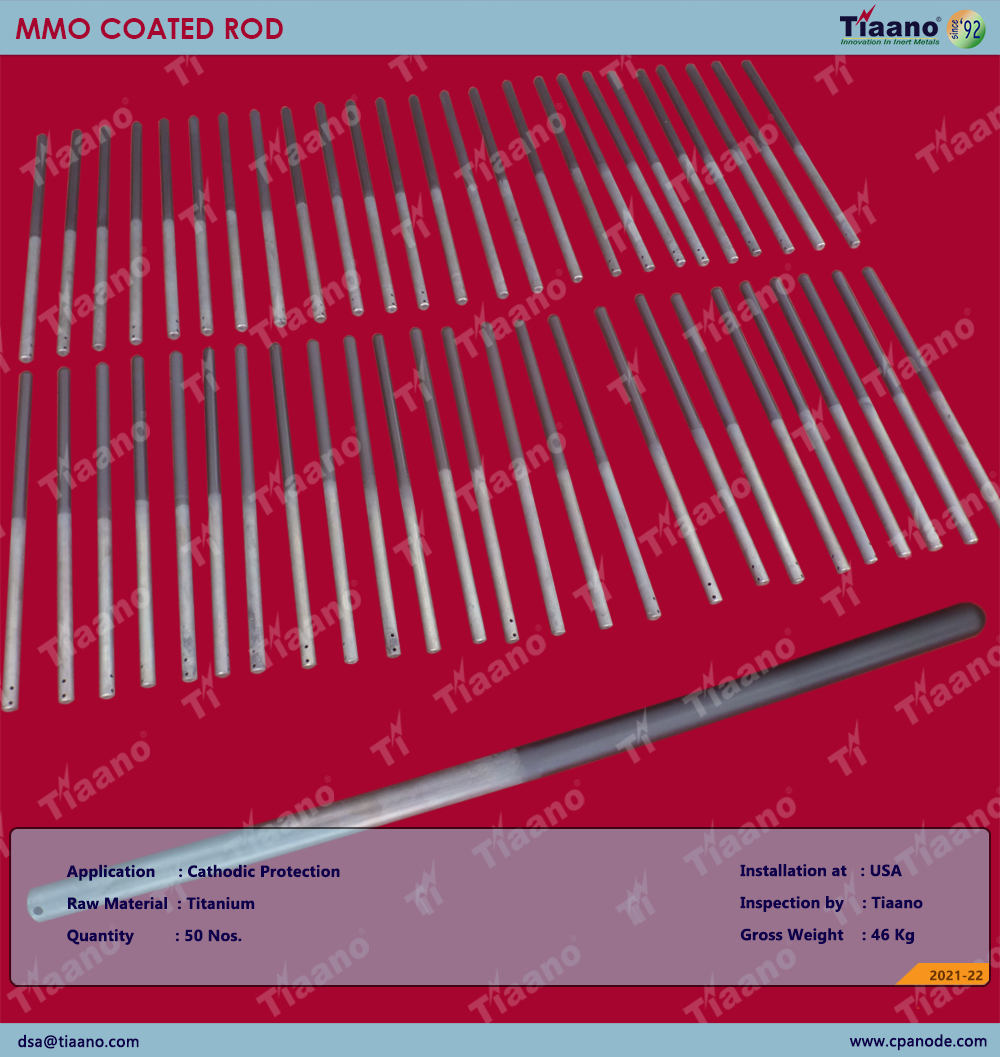

MMO Coated Tubular String for Cathodic Protection

We Tiaano do fabrication & supply of MMO Titanium tubular anodes by using titanium seamless tube and coated with platinum group precious metal mixed oxide coating. Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements

Mixed Metal Oxide Coated Titanium anode design for the demands of deep anode beds, shallow beds and the earth’s natural waters. MMO Tubular anodes are dimensionally stable anodes which remain constant throughout all of the anode life, thus providing a constant performance with a low resistivity MMO Titanium tubular anodes are a titanium tube base with a mixed metal oxide conductive coating and itself an excellent electronic conductor.

The design life of the anode varies with operating current in a variety of applications from seawater to soil. Tubular Anodes are available in a number of diameters, lengths, current carrying capacities and life ratings.

MMO tubular anode can be in single or in string, it is generally adopting titanium tubular as substrates and coated with a mixed metal oxide catalyst.

Mixed metal oxide based electrocatalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current..

Benefits of MMO Coated Tubular String:

· Lightweight/Durable

· High current output

· Low cost

· Dimensionally stable

· High cost performance

The specification of the below displayed MMO Coated Titanium Tubular String Anode

|

Material

|

Titanium

|

|

Coating

|

MMO

|

|

Country of origin

|

India

|

|

Thickness

|

0.9 mm

|

|

OD

|

25.4 mm

|

|

Length

|

500 mm

|

Cathodic protection is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. A simple method of protection connects the metal to be protected to a more easily corroded "sacrificial metal" to act as the anode.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

c2437e51-369e-48b1-b64a-29a4318cedb5|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

April 18, 2022 10:55 by

admin

adminCathodic protection is one of the main technique to prevent corrosion. Cathodic protection is of two types they are Impressed Current Cathodic Protection (ICCP) and Galvanic Protection also known as DCCP. Cathodic protection systems protects a wide range of metallic structures in various environments. Titanium tubular anodes are manufactured using titanium seamless tube and coated with platinum group precious metal mixed oxide coating.

MMO coated tubular string anodes are used to protect the pipe lines which is installed horizontal bed as well as vertical deep well with multi string /single string based on several design and field condition factors including current distribution requirements.

Applications:

- Salt, fresh and brackish water

- Deep well Anodes

- Marine applications

- Tank bottoms

- Underground pipelines

For more details visit these links:

www.cpanode.com,www.tiaanostore.in,www.tiaano.com

Follow us on:

Pinterest, Instagram, Facebook, Twitter

481fbd68-5498-4892-95c0-70a2fd3f5bd8|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

January 31, 2022 16:15 by

admin

adminCathodic protection system is a technique used to control a corrosion of a metal surface by making it the cathodic side of an electrochemical cell. Cathodic protection is an old and effective system that prevents forming rust in metal and helps in corrosion resistant. Corrosion can be prevented by eliminating the oxygen or the positively charged hydrogen ions. Two methods are available for applying cathodic protection they are:

- Impressed Current Cathodic Protection (ICCP)

- Galvanic Cathodic Protection

We, Ti Anode Fabricators Pvt. Ltd., developed an extremely strong and electrically low resistance centre crimp connection, which ensures the lowest possible electrical resistance (less than 1.0 Milli Ohm) between the cables and anode tube. The Platinum group Mixed Metal Oxide coating is a crystalline electrically conductive coating that activates and enables a titanium substrate to function as an anode. Whether operating in fresh water, seawater, soil, or mud. MMO Coatings are extremely stable even in very low pH environments.

Ti’s MMO titanium tubular anodes are coated with mixed metal oxide that has an extremely low consumption rate measured in milligrams per year. Unlike other types of anodes the consumption rate of MMO anode is negligible with the dimensions of the anode element remaining virtually unchanged during the operational service life of the anode. As a result, the power required to impress current will remain the same.

Advantages:

- Lightweight/Durable

- High current output

- Low cost

- Dimensionally stable

- High cost performance

Applications:

- Salt, fresh and brackish water

- Deep well Anodes

- Marine applications

- Tank bottoms

- Underground pipelines

Titanium tubular anodes are manufactured using titanium seamless tube and coated with platinum group precious metal mixed oxide coating. Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements.

For more details visit these links:

www.cpanode.com,www.tiaanostore.in,www.tiaano.com

Follow us on:

c533f3e0-ab95-4c01-9df5-e8ea992ee63f|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

June 18, 2021 09:56 by

admin

admin

The following are some of the advantages of the ICCP system:

Impressed Cathodic Protection System has several advantages over other types of cathodic protection systems because it makes use of an external power supply to power both the anode and cathode systems, making it possible to protect any structure, regardless of its size.

When compared to other prevention methods available on the market, the use of ICCP systems has a longer life span and greater durability.

The structure's life expectancy has been extended.

The anodes are small and lightweight, making them simple to install and store.

a9db9953-b8d5-47f3-9e94-42e711390677|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

May 26, 2021 14:55 by

admin

admin

Impressed current cathodic protection (ICCP) anodes are one of the most effective ways to prevent corrosion. They are one of the most innovative and cost-effective cathodic protection systems on the market. The ICCP system is a cathodic protection system that protects your equipment. We have three decades of ICCP anode manufacturing experience at Tiaano. Tiaano's ICCP technology provides one of the best cathodic corrosion protection in the world, with satisfied customers for the past three decades.

You may get more information on our Facebook page.

https://www.facebook.com/pg/Tiaano-ICCP-Anodes-125008582229120/posts/

100ee6e2-40b5-472b-9fbc-b1e2ac396dae|0|.0|27604f05-86ad-47ef-9e05-950bb762570c