May 31, 2023 10:15 by

admin

adminWe, Ti Anode Fabricators Pvt. Ltd., developed an extremely strong and electrically low resistance centre crimp connection, which ensures the lowest possible electrical resistance (less than 1.0 Milli Ohm) between the cables and anode tube. The Platinum group Mixed Metal Oxide coating is a crystalline electrically conductive coating that activates and enables a titanium substrate to function as an anode. Whether operating in fresh water, seawater, soil, or mud. MMO Coatings are extremely stable even in very low pH environments.

MMO titanium tubular anodes are coated with mixed metal oxide that has an extremely low consumption rate measured in milligrams per year. Unlike other types of anodes the consumption rate of MMO anode is negligible with the dimensions of the anode element remaining virtually unchanged during the operational service life of the anode. As a result, the power required to impress current will remain the same.

Cathodic protection system is a technique used to control a corrosion of a metal surface by making it the cathodic side of an electrochemical cell. Cathodic protection is an old and effective system that prevents forming rust in metal and helps in corrosion resistant. Corrosion can be prevented by eliminating the oxygen or the positively charged hydrogen ions.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

e0d76a54-491e-4750-9fb1-88da627f87fa|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

May 30, 2023 09:48 by

admin

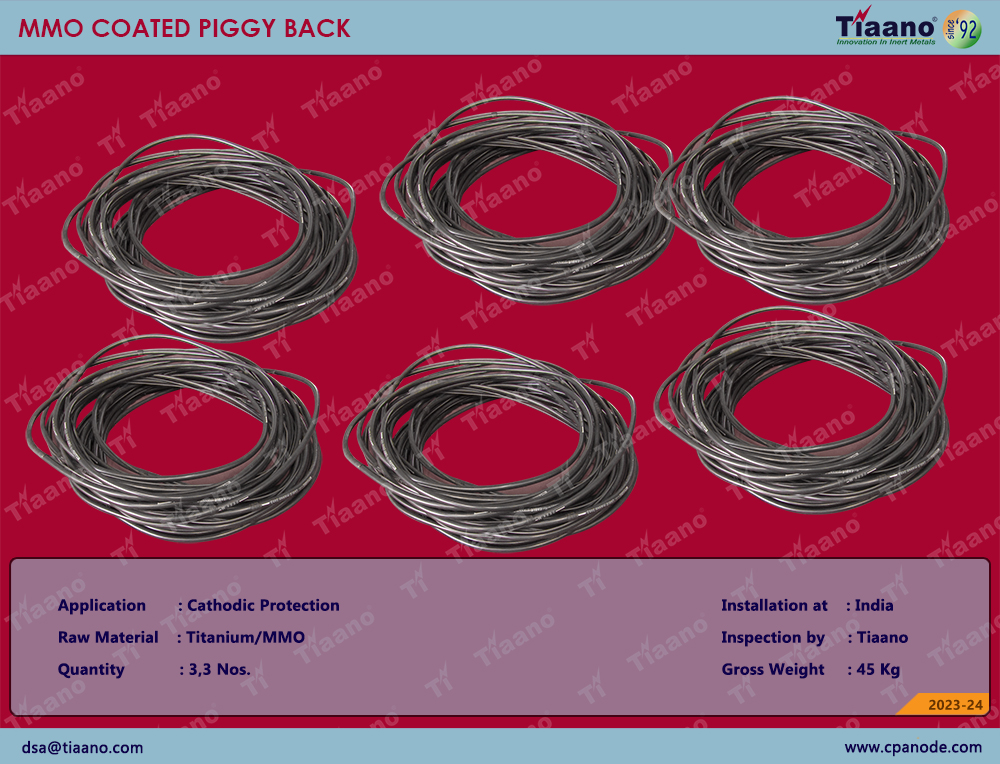

adminMMO piggyback anode is the flexible anode with a long life, which integrates the advantages of large current of MMO anode and excellent conductive performance. Due to its large current and small grounding resistance, it can be buried in the place far away from the anode structure.

Piggy pack anodes are used to protect the tank bottoms. It’s the easiest method of cathodic protection which may not need a weld at site and also easy to handle and install. Piggy pack wire anodes connected with cable by the way of Crimping and sealing with mastic and heat shrink sleeve procedure. The piggy pack anodes are inserted in the jacket with coke fill to sustain the conductivity of the anodes in the place where we install for cathodic protection.

Cathodic Protection is accomplished by applying a direct current to the tank surface of the metal, which causes the electrochemical potential of the structure to shift from a corroding state to a polarized and non-corroding state.

9bf8541d-f52c-4563-9ee2-4c773c3900fa|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

March 20, 2023 11:20 by

admin

admin

The invention relates to the field of cathodic protection of reinforced concrete structures, and in particular to a design of discrete anode for cathodic protection suitable for being installed inside holes or slits made in the concrete. The anodes commonly used for the cathodic protection of reinforced concrete consist of a titanium substrate coated with transition metal oxides or other types of catalysts for anodic oxygen evolution.

Discrete anodes are not suitable for all applications, especially for thin concrete element or where the reinforcement is randomly spaced within a structure. The main area of application of discrete anodes would be thick reinforced concrete elements, such as beams, headstocks or piles in tidal/ splash zones where the application of ribbon anodes leads to grout acidification in most cases. Having in mind the long term durability of the cathodic protection components installed permanently in concrete and the importance of delivering a CP system with low maintenance.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

3e9d0d52-b481-400c-9709-22d39105466d|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

December 19, 2022 12:22 by

admin

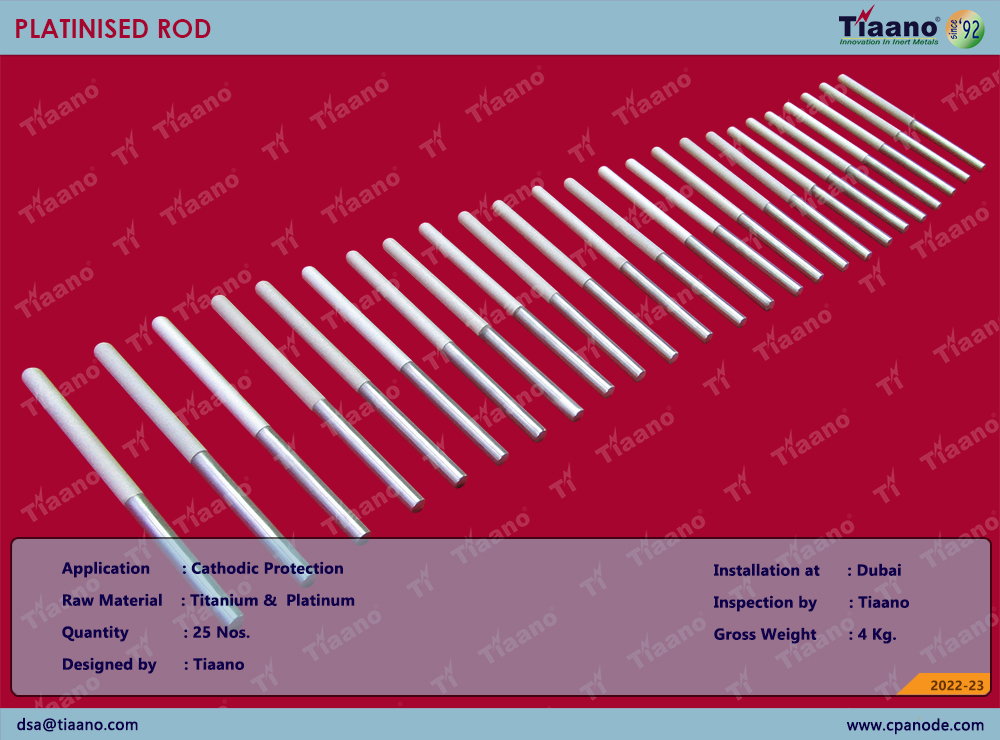

admin Platinized titanium and MMO coated titanium rod anodes are to be designed & manufactured by Ti Anode Fabricators Pvt Ltd, Chennai, India. Application: Deep & conventional ground beds. Jetties in fresh, brackish and salt-water electrolytes. Water tanks. Lock Gates. Intake Screens. Marine application.

Substrate: Solid Titanium and Niobium & Copper cored Ti. Catalyst for surface Coating: Platinum Mixed Metal Oxide.

platinised titanium and niobium probe / cantilever type anodes are also available for use in internal ICCP of process vessels such as pipes, condenser water boxes and heat exchangers where the interior is difficult to access and its space limited. such anodes are often mounted through the vessel shell, with the anode part of the probe extending into the vessel, and wire connections made to the probe on the exterior of the vessel.

Tiaano offer platinised and niobium cantilever (probe) anodes for this application (medium seawater, fresh water and brackish water) also tiaano offer platinised rods and tubes suitable for cantilever (probes).

the primary use of platinised titanium anodes is in the field of cathodic protection. the anodes are used in structures buried in soil and the steel exposed to marine environments such as oil and gas producing platforms, ships, oil well casing and jetties.

platinised titanium anodes synergistically combine the favorable electrochemical features of platinum (pt) with the corrosion resistance and other characteristics of titanium. they are anodes normally produced by the electrochemical deposition of a very thin layer of platinum metal onto a titanium substrate. these anodes operate as inert anodes with high durability and are preferred because they remain insoluble in common electrolytes.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

74fd8c41-97c4-4a75-908b-6e54c3202f03|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

December 14, 2022 14:00 by

admin

adminCathodic protection system is a technique used to control a corrosion of a metal surface by making it the cathodic side of an electrochemical cell. Cathodic protection is an old and effective system that prevents forming rust in metal and helps in corrosion resistant. corrosion can be prevented by eliminating the oxygen or the positively charged hydrogen ions. Two methods are available for applying cathodic protection they are:

· Impressed Current Cathodic Protection (ICCP)

· Galvanic Cathodic Protection

We, Ti Anode Fabricators Pvt. Ltd., developed an extremely strong and electrically low resistance center crimp connection, which ensures the lowest possible electrical resistance (less than 1.0 Milli Ohm) between the cables and anode tube. The Platinum group Mixed Metal Oxide coating is a crystalline electrically conductive coating that activates and enables a titanium substrate to function as an anode. Whether operating in fresh water, seawater, soil, or mud. MMO Coatings are extremely stable even in very low pH environments.

MMO Titanium tubular anode are coated with mixed metal oxide that has an extremely low consumption rate measured in milligrams per year. Unlike other types of anodes the consumption rate of MMO anode is virtually unchanged during the operational service life of the anode. As a negligible with the dimensions of the anode element remain result, the power required to impress current will remain the same.

Advantages:

· Lightweight/Durable

· High current output

· Low cost

· Dimensionally stable

· High cost performance

Applications:

· Salt, fresh and brackish water

· Deep well Anodes

· Marine applications

· Tank bottoms

· Underground pipelines

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

a611d954-2d83-44f5-bdd4-ae6aa7552479|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

December 13, 2022 12:27 by

admin

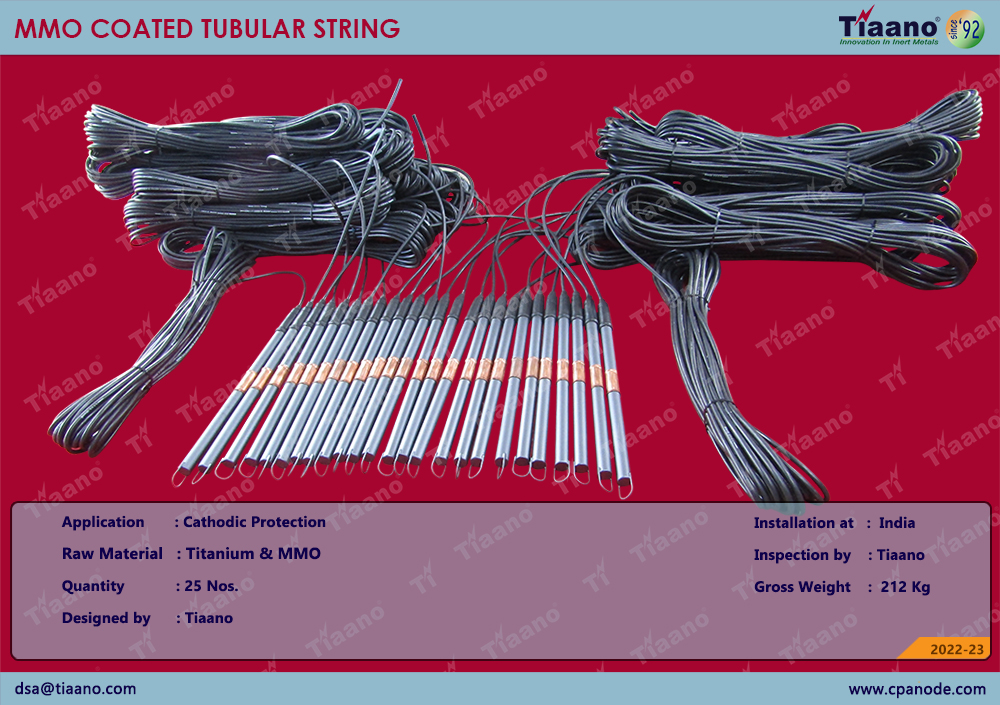

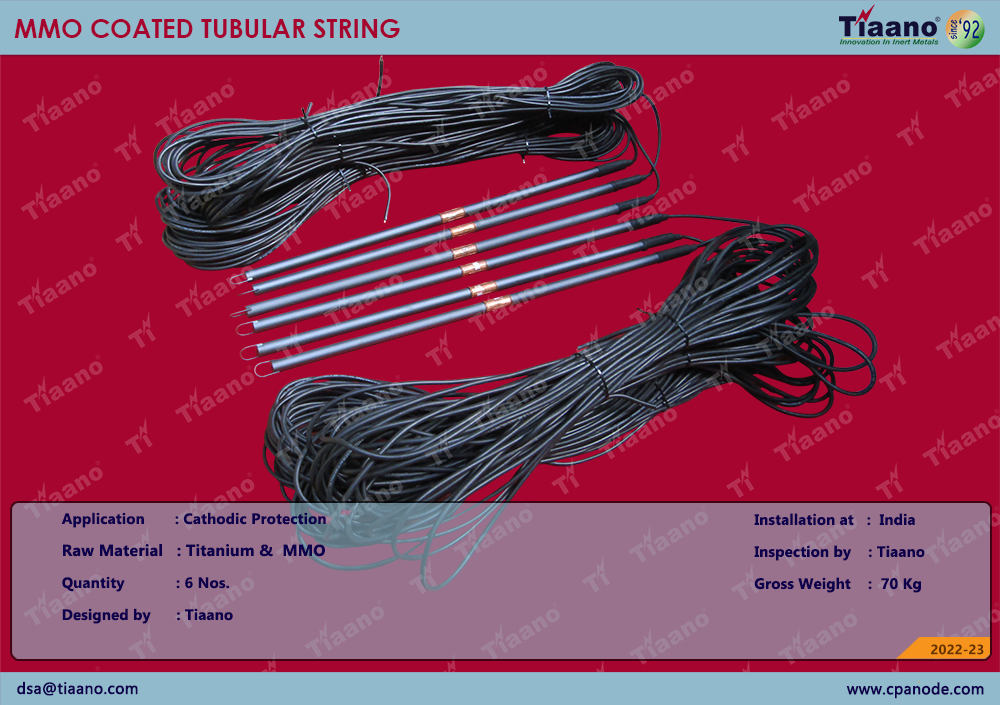

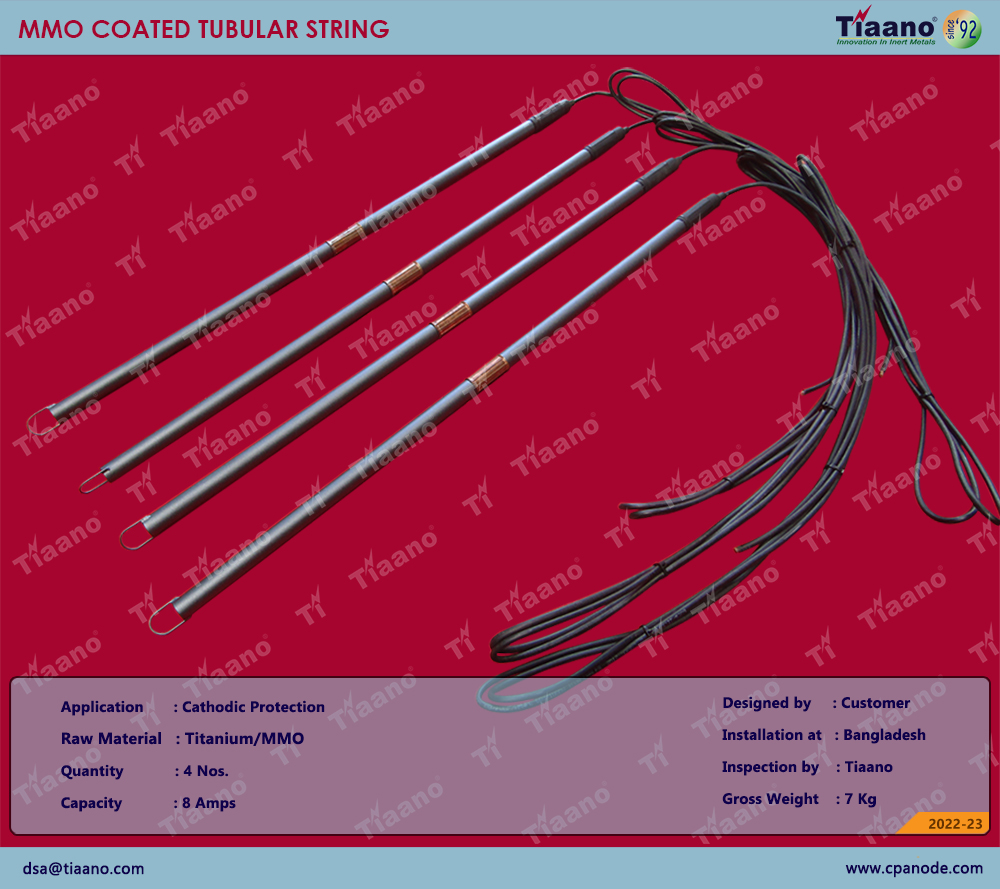

adminTitanium tubular anodes are manufactured using titanium seamless tube and coated with platinum group precious metal mixed oxide coating. Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements

Mixed Metal Oxide Coated Titanium anode design for the demands of deep anode beds, shallow beds and the earth’s natural waters. MMO Tubular anodes are dimensionally stable anodes which remain constant throughout all of the anode life, thus providing a constant performance with a low resistivity

MMO Titanium tubular anodes are a titanium tube base with a mixed metal oxide conductive coating and itself an excellent electronic conductor.

The design life of the anode varies with operating current in a variety of applications from seawater to soil. Tubular Anodes are available in a number of diameters, lengths, current carrying capacities and life ratings.

MMO tubular anode can be in single or in string, it is generally adopting titanium tubular as substrates and coated with a mixed metal oxide catalyst.

Mixed metal oxide based electro catalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current.

Mixed Metal Oxide anodes are typically rated for a given output and life, for example 5 amps at 20 years. Within the normal range of current discharge for MMO anodes, this relationship is linear. The same 5 amp anode rated for 20 years of service would provide 40 years if only operated at 2.5 amps.

Benefits of MMO Coated Tubular String:

· Lightweight/Durable

· High current output

· Low cost

· Dimensionally stable

· High cost performance

MMO Coated Tubular String - Applications:

· Salt, fresh and brackish water

· Deep well Anodes

· Marine applications

· Tank bottoms

· Underground pipelines

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

6b7384d7-5139-4407-b8c9-c8fc1a6ee91b|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

December 2, 2022 11:09 by

admin

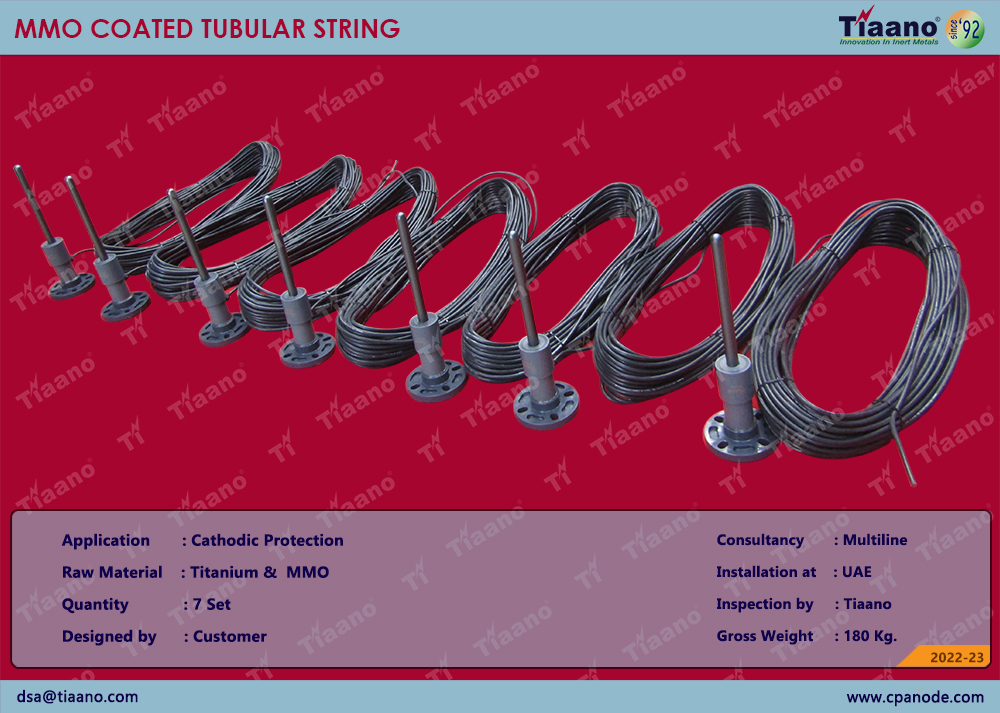

adminTitanium tubular anodes are manufactured using titanium seamless tube and coated with platinum group precious metal mixed oxide coating. Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements

Mixed Metal Oxide Coated Titanium anode design for the demands of deep anode beds, shallow beds and the earth’s natural waters. MMO Tubular anodes are dimensionally stable anodes which remain constant throughout all of the anode life, thus providing a constant performance with a low resistivity.

MMO Titanium tubular anodes are a titanium tube base with a mixed metal oxide conductive coating and itself an excellent electronic conductor.

The design life of the anode varies with operating current in a variety of applications from seawater to soil. Tubular Anodes are available in a number of diameters, lengths, current carrying capacities and life ratings.

MMO tubular anode can be in single or in string, it is generally adopting titanium tubular as substrates and coated with a mixed metal oxide catalyst.

Mixed metal oxide based electro catalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current.

Benefits of MMO Coated Tubular String:

Lightweight/Durable

High current output

Low cost

Dimensionally stable

High cost performance

MMO Coated Tubular String - Applications:

Salt, fresh and brackish water

Deep well Anodes

Marine applications

Tank bottoms

Underground pipelines

F For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

6cbc8cc8-7b2c-4a72-a256-193a8df6c62c|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

October 31, 2022 16:48 by

admin

admin Cathodic protection is the most common electrochemical technique used to prevent corrosion on pipelines, storage tanks, ship hulls, underground tanks etc. The process occurs when a DC current is passed through an anode and cathode so that the metal becomes cathodic and prevents corrosion.

Cathodic protection is one of the main technique to prevent corrosion. Cathodic protection is of two types they are Impressed Current Cathodic Protection (ICCP) and Galvanic Protection also known as DCCP. Cathodic protection systems protects a wide range of metallic structures in various environments.

Titanium tubular anodes are manufactured using titanium seamless tube and coated with platinum group precious metal mixed oxide coating.

Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements.

Mixed metal oxide based electro catalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current.

Mixed Metal Oxide anodes are typically rated for a given output and life, for example 5 amps at 20 years. Within the normal range of current discharge for MMO anodes, this relationship is linear. The same 5 amp anode rated for 20 years of service would provide 40 years if only operated at 2.5 amps.

Benefits of MMO Coated Tubular String:

· Lightweight/Durable

· High current output

· Low cost

· Dimensionally stable

· High cost performance

MMO Coated Tubular String - Applications:

· Salt, fresh and brackish water

· Deep well Anodes

· Marine applications

· Tank bottoms

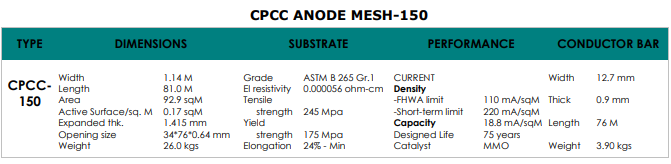

The specification of the below displayed MMO Coated Titanium Tubular String Anode

|

Material

|

Titanium

|

|

Dimensionally

|

Stable

|

|

Thickness

|

0.9 mm

|

|

Country of origin

|

India

|

|

OD

|

25.4 mm

|

|

Length

|

500 mm

|

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

a0ca1f8b-bbae-43f8-a311-0c6ee7a690bc|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

October 27, 2022 11:31 by

admin

adminAg/Agcl Reference Electrode is the silver/silver chloride reference electrode is composed of a silver wire, sometimes coated with a layer of solid silver chloride, immersed in a solution that is saturated with potassium chloride and silver chloride.

Platinum titanium is a platinum metal oxide or platinum layer-coated on a titanium substrate. It is non-consumption, durable, and insoluble in the electrolyte. We can use platinum titanium anode for cathodic protection and electroplating.

Zinc Reference electrodes are generally implemented for the purpose of monitoring the anode in cathodic protection of buried or immersed metallic structures. It is made of high-purity Zinc alloy, ensuring accuracy and stability of potential measurements.

The electrode frame is made of stainless steel, coated carbon steel or Rubber. The electrode can be designed to fix in the structure. By means of specifically designed supports.

Cu/CuSO4 portable reference electrode implements a major usage in the cathodic protection System. Reference Electrode are in different shapes like disc, rod and strip with different dimension, which is also installed in the Heat exchanger to monitor the current supply of cantilever anodes.

MMO coated Canister anodes are commonly used for impressed current anode cathodic protection applications. These can be used to protect buried metallic piping in congested plant environments, to protect distribution or transmission pipelines in either distributed shallow ground beds or as horizontal remote ground bed anodes, and to protect other structures such as above ground or buried tanks and piling systems.

- Flexibility to meet various user needs;

- Produce complex shape of the anode;

- Energy-saving;

- Lightweight (especially the mesh grid anode);

- Longer working life under higher current density;

- Firm titanium structure, less deformation;

- Second platinized allowed;

- Uniform deposit, final products with high quality.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

2d2a88cb-3b4d-4659-962e-3192c0b71231|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

October 11, 2022 17:20 by

admin

adminWe, Ti anode fabricators Pvt. Ltd., is familiar in manufacturing and supplying of Platinum Plated Cantilever for impressed current cathodic production (ICCP)

Platinum is an amazing catalyst because of its high conductivity and low utilization rate. Platinum testimony made by electroplating strategy over a high erosion opposition substrate. Platinum is a most un-responsive metals that has surprising protection from consumption, even at high temperatures. Cathodic security is a technique for forestalling erosion on lowered and underground metallic designs. Cathodic insurance is one of the best technique for forestalling consumption on a metal surface.

Platinized cantilever anode is utilized for safeguarding pipeline internals, pull and condenser box inner for a long time and more by applying DC current with transformer rectifier. Ordinarily titanium is notable for its high protection from erosion both water and chemical media but titanium is the poor electricity conductor. So we use platinum/MMO plating/coating to expand the conductivity.

Impressed Current Cathodic Protection is one of the best system to prevent corrosion by passing DC current through anodes and cathodes from one end to another end. platinised titanium anode is used for protecting pipeline internals, suction and condenser box internal for 30 years and more by applying DC current with transformer rectifier. We use platinum/ MMO plating/ coating to increase the conductivity.

ADVANTAGES:

- Low utilization rate that preserves valuable platinum.

- Favorable dimensional stability.

- Corrosion resistance ensures durability with easy maintainability.

- Light weight, as well as favorable current distribution in electroplating.

Applications:

- Heat exchangers.

- Pumps

- Valves

- Pipes

- Marine application

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

f021753c-96ff-43c1-afbb-eb8ed419a280|0|.0|27604f05-86ad-47ef-9e05-950bb762570c