January 21, 2020 16:23 by

admin

admin

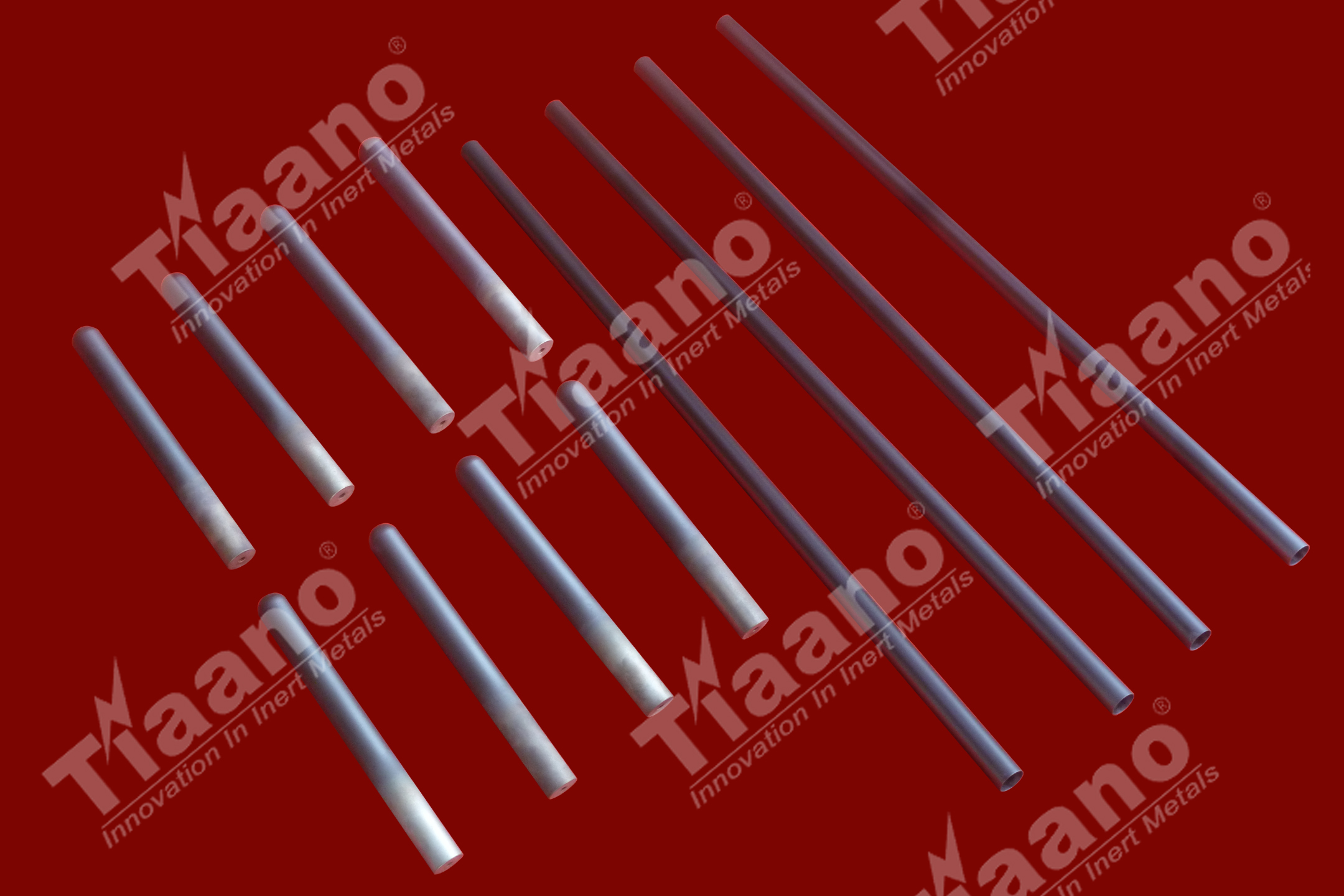

Platinum is an excellent anode material due to its high conductivity and low consumption rate. Due to its high cost, Platinum is made practical for use by electroplating a thin layer over a high corrosion resistance substrate. Since Titanium, Niobium and Tantalum substrates are having the ability to form an insulating oxide film under anodic conditions, they are all most commonly used as anode in ICCP.

The usual thickness of the platinum coating is approximately 2.5 microns, however, this coating thickness should be increased to 5.0 microns for harsher environments. The base metal is available in a wide variety of standard shapes - rods, tubes, mesh, etc. - which can be fabricated into non-metallic mounts for attachment to the structure to be cathodic protection.

The advantage of Platinised titanium anodes is that they can be operated at high current densities with very low consumption rates.

PLATINISED ROD

FEATURES

• Anodes can work at high current densities without decomposition or dissolving.

• Favorable strength to weight ratio.

• Anodes can be smaller and more compact than comparable conventional anodes.

• Can be manufactured in a wide variety of shapes and sizes.

• Lightweight support tube installation for Pt Ti anode installation.

Additional Information:

- Production Capacity: Custom Size

- Delivery Time: 3 Weeks

8cba8f7e-0c66-44c0-84de-74db47cec371|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

January 9, 2020 10:57 by

admin

adminGALVANISED STEEL CANISTER

Canister anodes are made from metallic alloys like steel with more negative electrochemical potential than the object to be protected. They are usually filled with coke fill to make a conductivity of burial anodes.Canister length and dia will be customized

Once at the jobsite and just prior to installation into the ground, it is suggested that small holes or slots be cut into the steel canister to allow any available groundwater into the canister. Care should be taken when cutting these hole or slots to avoid damage to the anode or anode cable.

Tiaano supplied Tubular anodes with steel canisters.

bf01ad49-90af-41ec-a1b5-c97bfe4b21ad|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

January 6, 2020 13:46 by

admin

adminMMO Coated rod & MMO Coated tube – Spares for Cantilever anode and Tubular anode for cathodic protection:

We design, manufacturing and supply of MMO & Platinum plated Titanium and Niobium anodes for Impressed Current Cathodic Protection (ICCP). According to the customer’s requirement we manufacture the anodes from copper cored titanium and copper cored niobium too. Our anodes are gone through the accreditation test by M/s. TWT, London as per NACE standard TMO 294-200. Our MMO coated / Platinized anodes are specified as…

Ø Made from seamless Titanium tubes: Single or multi string anodes, Cantilever and probe anodes, Civil probe or discrete tube anodes, Liner loop tube anodes, Tube anodes.

Ø Made from titanium / niobium or their copper cored rods: Cantilever anodes, Heater probe anodes, Canister anodes, Suspended rod anodes, Rod anodes.

Ø Made from titanium and niobium wires: Canister anodes, Expanded spring anodes, Anode flex, Piggy back anodes, Linear loop anodes, Wire anodes.

Ø Made from Titanium and Niobium sheets: Strip canister anodes, Strip anodes, Elliptical anodes, Disc anodes, Solid ribbon anodes, Pyramid anodes, Conductor bar.

Ø Made from Titanium expanded metal mesh: Mesh canister anodes, Ribbon mesh anodes, discrete anodes, Star guard anodes, Anode mesh.

Ø Reference electrodes from MMO coated titanium rods and zinc cast rods.

Tiaano supplying all cathodic protection anodes as well as spares of CP anodes such as mmo coated & platinized titanium rod, tube, mesh, plate etc., in larger quantity to our regular customers all over the world.

Our recent supply to our Indonesian customer:

731cf6aa-24e4-42b7-bed5-69d815d8f22f|1|5.0|27604f05-86ad-47ef-9e05-950bb762570c

January 3, 2020 11:41 by

admin

adminAn impressed current cathodic protection system (ICCP) is the technology to protect the concrete structure, pipelines, jetties and other materials which are corroded with natural or chemical elements.

Anodes for ICCP systems are available in a variety of shapes and sizes in different application. These consist of anodes connected to a DC power source, often a transformer-rectifier connected to AC power. In the absence of an AC supply, alternative power sources may be used, such as solar panels, wind power or gas powered thermoelectric generators

Ti Anode Fabricators Pvt Ltd., India - manufactures CPCC Piggyback Wire Anodes at their in-house facilities in India, for impressed current cathodic protection application. Using following alternative anode combinations are been supplied based on the application and customer''s interest

Our recent supply of MMO Coated wire 2500 mtrs. to our Gujarat customer:

78204962-e805-4169-a151-a72db832eda0|1|5.0|27604f05-86ad-47ef-9e05-950bb762570c

December 14, 2019 11:48 by

admin

adminMMO COATED TUBE AND ITS ACCESSORIES

MMO COATED TUBULAR ANODE FOR CATHODIC PROTECTION USED TO PROTECT THE PIPE LINES, DEEP WELLS AND INFRASTRUCTURE LAID IN DIFFERENT APPLICATION LIKE SEA WATER, BRAKISH WATER, SAND ETC.,

MMO COATED TUBULAR ANODE

MMO COATED TUBULAR ANODE will be supply in two types

1. Single string (consist of a single anode with cable)

2. Multi string (consist of two or more anodes connecting with a string)

Anodes are connected with the cable by a) LIDA connection b) CPCC connection.

(20 years Lifetimes stated are nominal, we can supply Amps / life different to stated standards on request)

TIAANO' S RECENT SUPPLY TO HYDERABAD - MMO COATED TUBULAR ANODE (SINGLE STRING)

19043e9d-838d-49dc-8b05-bcd849970688|1|5.0|27604f05-86ad-47ef-9e05-950bb762570c

December 11, 2019 17:00 by

admin

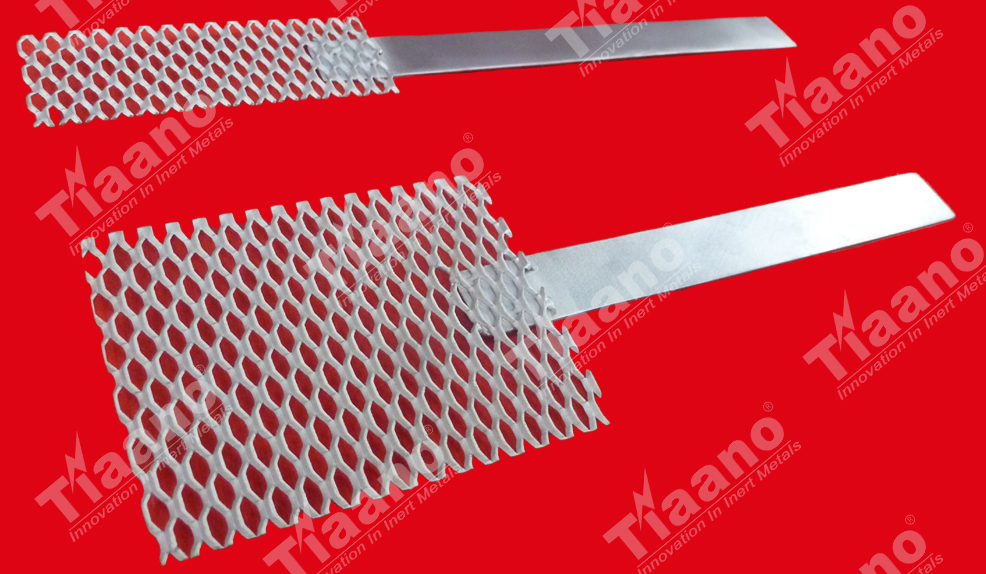

adminPLATINUM PLATED MESH for electro oxidation to treat the water

In recent years, there has been increasing interest in finding innovative solutions for the efficient removal of contaminants from water, soil and air. Government also strictly insist the industries to make a zero discharge and chemical contamination free soil and water to protect our environment.

ELECTRO OXIDATION AND ELECTRO COAGULATION process together treats the water as a disinfection using our Platinized titanium mesh.

By passing the DC current through Platinised titanium mesh leads to remove BOD COD ratio landfill leachate was conducted by means of electrochemical oxidation process. Electrochemical oxidation process is effective in removing pollutants from landfill leachate.

Depending on the effluent nature, an increase of the conductivity of the solution may be required: the value of 1000 mS/cm is commonly taken as a threshold. Salts like sodium chloride can be added to the solution, acting as electrolytes thus raising the conductivity. Typical values of salts concentration are in the range of few grams per liter, but the addition has a significant impact on power consumption and can reduce it by up to 30%.

Electro-oxidation (EO), also known as anodic oxidation, is a technique used for wastewater treatment, mainly for industrial effluent playing roll in advanced oxidation process. The most general layout comprises two electrodes, operating as anode and cathode, connected to a power source.

Electro-oxidation is an excellent and eco-friendly technique for the removal of persistent organic contaminants, electrochemical advanced oxidation processes are ordinarily used to remove COD and BOD presence in the water.

Platinum electrode provides good conductivity and they are inert and stable at high potentials. At the same time, the oxygen evolution over potential is low and comparable to that of graphite. As a result, electro-oxidation with Platinum electrodes usually provides low yield due to partial oxidation of the compounds. The contaminants are converted into stable intermediates, difficult to be broken down, thus reducing current efficiency for complete mineralization

However, this technique suffers the primary disadvantage of high energy consumption and low current efficiency.

Tiaano supplying the ELECTRO OXIDATION systems and its spares for the different regions. Also we are supplying the MMO Coated plates (titanium) instead of platinized titanium mesh to treat the water.

PLATINISED PLATED MESH

26820561-ab08-4fa7-8006-9991219aa96d|1|5.0|27604f05-86ad-47ef-9e05-950bb762570c

December 11, 2019 14:22 by

admin

adminMMO Coated Mesh anodes for Concrete protection.

Tiaano placing major role in cathodic protection anodes.

Cathodic protection reduces costs for future repair work and extends the life expectancy of your concrete structure. Our MMO coated mesh anodes with impressed current protects the steel structure from erosion and corrosion.

Our recent supply to USA

.jpg)

031f2ed2-4fba-43c3-bb69-3b4fa1861003|1|5.0|27604f05-86ad-47ef-9e05-950bb762570c

December 4, 2019 13:49 by

admin

adminMMO Coated cantilever & Zinc Reference electrodes

MMO Coated cantilever anode are used to protect the surface of gigantic pump internals and condenser box where the sea water pass through in it. These anodes are use to protect the pump internals from erosion and corrosion with impressed current.

Reference electrodes are used in locations where a constant, stable reference where our anodes are installed with constant potential rectifiers.

Normally we can use wide variety of reference electrodes like zinc, silver chloride or copper sulfate reference electrodes for pump internal, condenser water box/vessel applications to monitor the cathodic protection anodes activeness.

Tiaano supplying MMO & platinum plated cantilever anodes and zinc reference electrodes for cathodic protection.

Recent supply for our Singapore client

e1b37304-b7bf-41f5-a229-3e6b82593924|1|5.0|27604f05-86ad-47ef-9e05-950bb762570c

November 21, 2019 15:07 by

admin

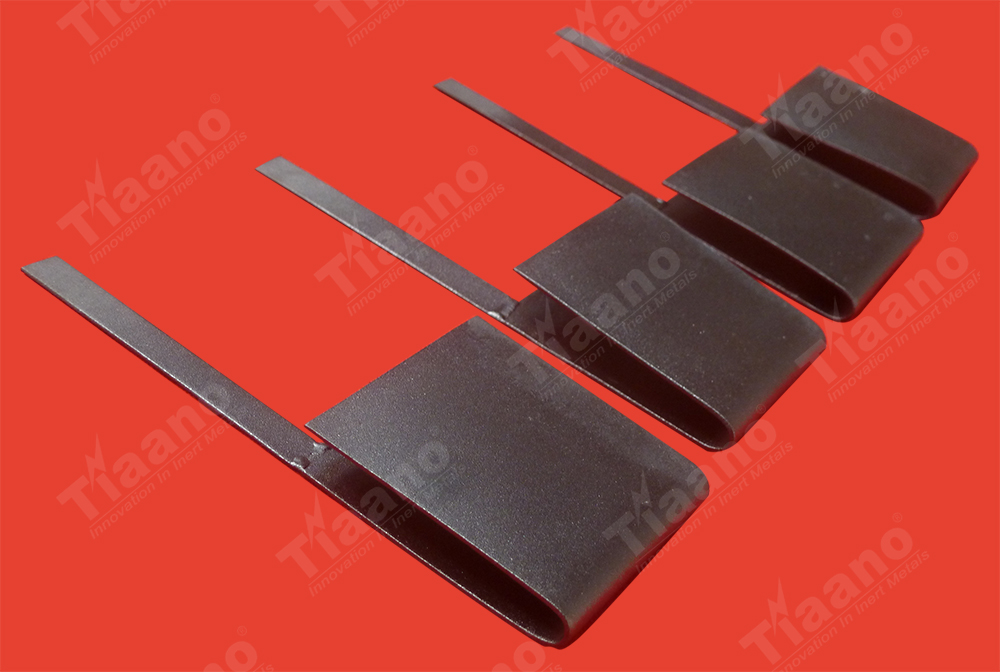

adminPlatinized FRP insulated strip for Cathodic protection in ship hull protection

Platinized Titanium anodes take advantage of the low consumption rate and high current density. Voltages in excess of 10 Volts will result in severe pitting of the titanium core causing premature failure. Exterior protection of ships hulls - anodes in the shape of plates, discs or strips

Platinized FRP insulated strip Anode with impressed current leads to protect the hull of the ships. Negative terminal which is connected to ship hull and positive terminal with impressed current anodes.

Underwater steel structures protection like wharves, jetties, sheet pile walls and piers. Usually rod type anodes distributed throughout the structure to be protected to give a good overall protective current distribution.

Change in the potential of an electrode as the result of current flow to or from that electrode. Also, a change in the potential of a corroding metal from its natural steady-state value, as a result of current flow. “Depolarization” is the reverse process of Polarization. Depolarization is sometimes referred to as "hypo polarization”.

Tiaano supply

Tiaano is well known for ICCP (Impressed Current Cathodic Protection) anodes and supplying anodes nearly 63 countries.

Our anodes are gone through the accreditation test by M/s. TWT, London as per NACE standard TMO 294-200

PLATINISED FRP INSULATED STRIP

c2f35d88-fecc-4899-a1eb-f7760d324427|1|5.0|27604f05-86ad-47ef-9e05-950bb762570c

November 13, 2019 12:12 by

admin

adminMMO COATED DSA PLATES for electro oxidation to treat the water

In recent years, there has been increasing interest in finding innovative solutions for the

efficient removal of contaminants from water, soil and air. Government also insist the industries to make a zero discharge and chemical contamination free to protect our environment.

ELECTRO OXIDATION AND ELECTRO COAGULATION process together treats the water as a disinfection using our MMO coated plates with the catalyst of Ruthenium Oxide (RuO2).

Treatment of a low BOD COD ratio landfill leachate was conducted by means of electro chemical oxidation process. Electrochemical oxidation process is effective in removing pollutants from landfill leachate.

Electro-oxidation (EO), also known as anodic oxidation, is a technique used for wastewater treatment, mainly for industrial effluent playing roll in advanced oxidation process. The most general layout comprises two electrodes, operating as anode and cathode, connected to a power source.

Electro-oxidation is an excellent and eco-friendly technique for the removal of persistent organic contaminants, electrochemical advanced oxidation processes are ordinarily used to remove COD and BOD presence in the water. However, this technique suffers the primary disadvantage of high energy consumption and low current efficiency.

Tiaano supplying the ELECTRO OXIDATION AND ELECTRO COAGULATION systems. Also we are supplying the MMO Coated plates (titanium) used in the system.

We, the Ti Anode Fabricators private limited, chennai supplying different types of MMO (mixed metal oxide)Coated plates for Water oxidation.

MMO Coated PLATES :

f094b22b-8f44-406f-bb7f-45724c83fafa|1|5.0|27604f05-86ad-47ef-9e05-950bb762570c